quality CNC punching

In the modern metalworking industry, CNC punching has become the preferred processing method for many companies due to its superior performance.

Advanced CNC Technology

CNC punching, or computer numerically controlled punching, utilizes advanced numerical control systems to precisely control the punching process. Operators simply input the design drawings into the control system, and the equipment accurately performs the punching operation according to the pre-set program. This digital control method significantly improves processing accuracy and repeatability, eliminating errors caused by human factors and ensuring that each stamped part meets consistent high-quality standards.

Efficient Production Capacity

CNC punching equipment boasts high-speed punching capabilities, enabling it to complete large volumes of punching tasks in a short period of time. Its rapid die change system makes switching between different product specifications efficient and convenient, significantly shortening production cycles. Compared to traditional stamping methods, CNC punching can increase production efficiency several times, meeting the needs of large-scale production and saving companies significant time and costs.

Wide Material Compatibility

CNC punching is suitable for a wide range of metal materials, including carbon steel, stainless steel, and aluminum alloys. It can accurately punch both thin and medium-heavy plate. This has led to its widespread application in numerous industries, including automotive manufacturing, electronics, and aerospace. In automotive parts production, CNC punching can create a variety of complex body parts; in the electronics sector, it can stamp out precise circuit board brackets and other components.

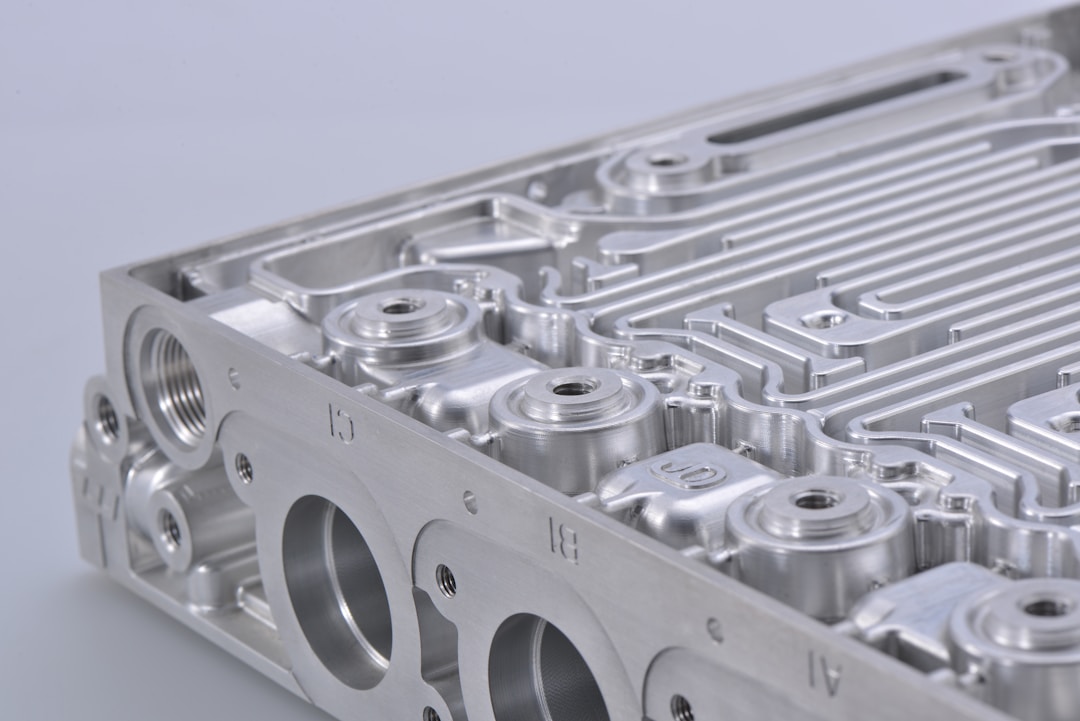

Advantages of Complex Shape Processing

This technology easily enables the stamping of complex shapes. Through advanced programming and mold design, it can produce stamped parts with various features, such as holes, slots, and protrusions, meeting the diverse design requirements of different products. Furthermore, the stamping process ensures smooth edges and dimensional accuracy, facilitating subsequent processing and assembly.

With its high precision, high efficiency, wide material compatibility, and ability to process complex shapes, CNC punching has brought new development opportunities to the metalworking industry, making it an ideal choice for companies seeking to improve product quality and production efficiency.

Related news

2025-12-10

Inquiry Hotline:

Inquiry Hotline: