Material selection and performance optimization in DMLS prototyping manufacturing

In DMLS prototyping manufacturing, material selection and performance optimization are crucial links.

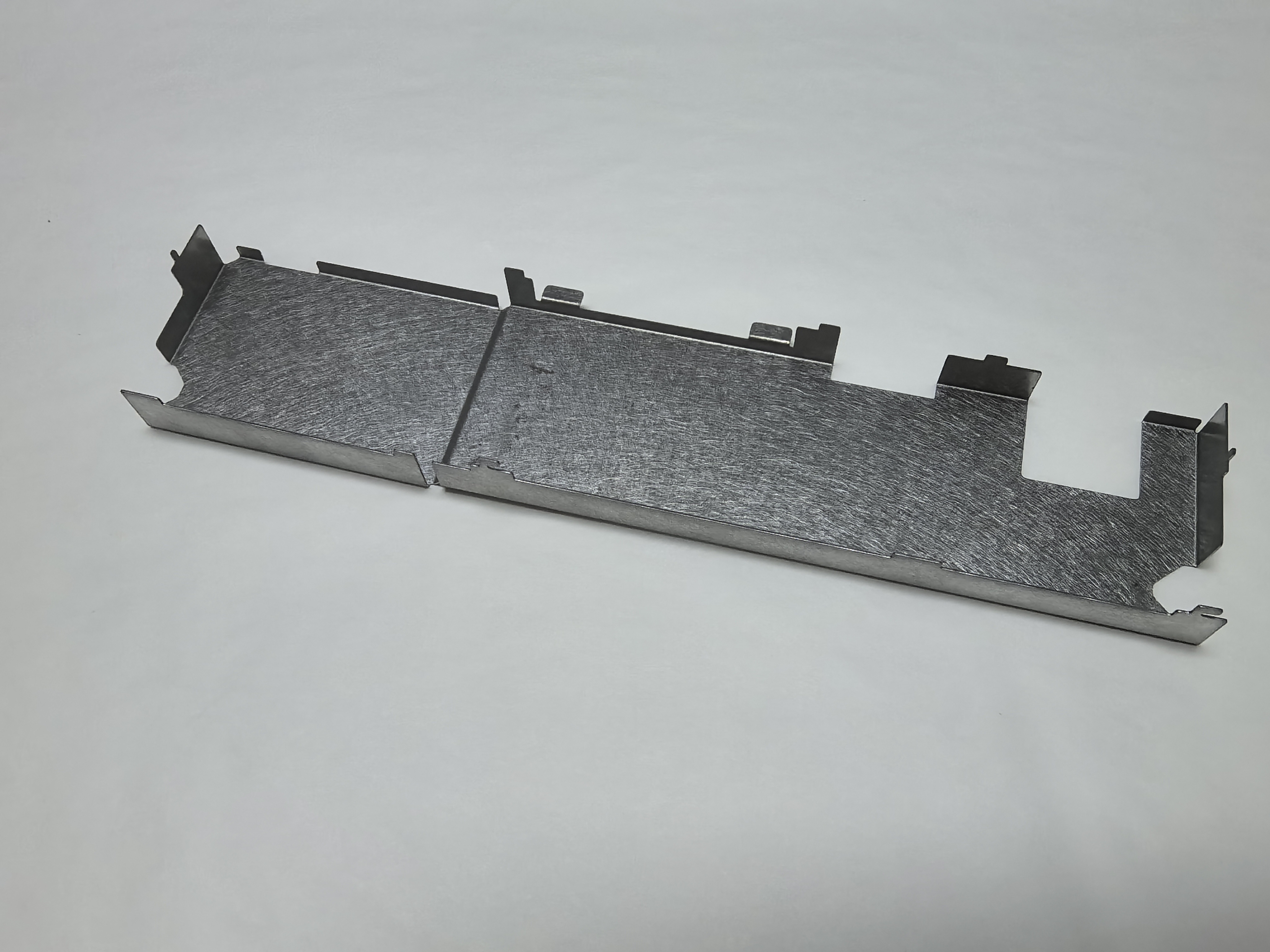

First of all, material selection directly affects the performance of the prototype. Common materials used for DMLS are stainless steel, titanium alloy, cobalt-chromium alloy, etc. Stainless steel has good corrosion resistance and mechanical properties, and is suitable for manufacturing prototypes that require certain strength and corrosion resistance, such as mechanical parts prototypes, simple molds, etc. Titanium alloy stands out for its high strength, low density and excellent biocompatibility, and is highly favored in prototype manufacturing in fields with demanding performance requirements such as aerospace and medical devices. Cobalt-chromium alloy excels in high temperature performance and wear resistance, and can be used to manufacture prototype parts that withstand high temperature and wear environments.

Performance optimization is the key to improving the quality of DMLS prototyping. For material performance optimization, the first thing to consider is the powder properties. The particle size distribution and sphericity of the powder will affect the density of sintering. Fine powders with uniform particle size distribution and high sphericity can improve the density of sintering, thereby improving the mechanical properties of the prototype. Secondly, the adjustment of sintering process parameters is of great significance to performance optimization. Parameters such as laser power, scanning speed, and scanning spacing interact with each other. Appropriately increasing the laser power and reasonably controlling the scanning speed and spacing can reduce internal defects and improve the density and strength of the prototype.

In addition, post-processing processes are also an important part of performance optimization that cannot be ignored. For example, heat treatment can improve the microstructure of the material, eliminate internal stress, and further improve the strength and hardness of the material. Post-processing methods such as machining can make the prototype achieve higher dimensional accuracy and surface finish.

In DMLS prototyping manufacturing, careful selection of materials and optimization of material properties through powder property optimization, process parameter adjustment and post-processing processes are the inevitable requirements for manufacturing high-quality DMLS prototyping.

Related news

2025-12-10

Inquiry Hotline:

Inquiry Hotline: