How to Use SLS Prototyping to Improve Product Precision and Strength

In product R&D and industrial manufacturing, precision and strength are core indicators of prototype quality. With the development of rapid prototyping technology, SLS has become an important tool for improving prototype precision and strength. Its unique molding principles and material selection give SLS significant advantages in functional verification and structural optimization.

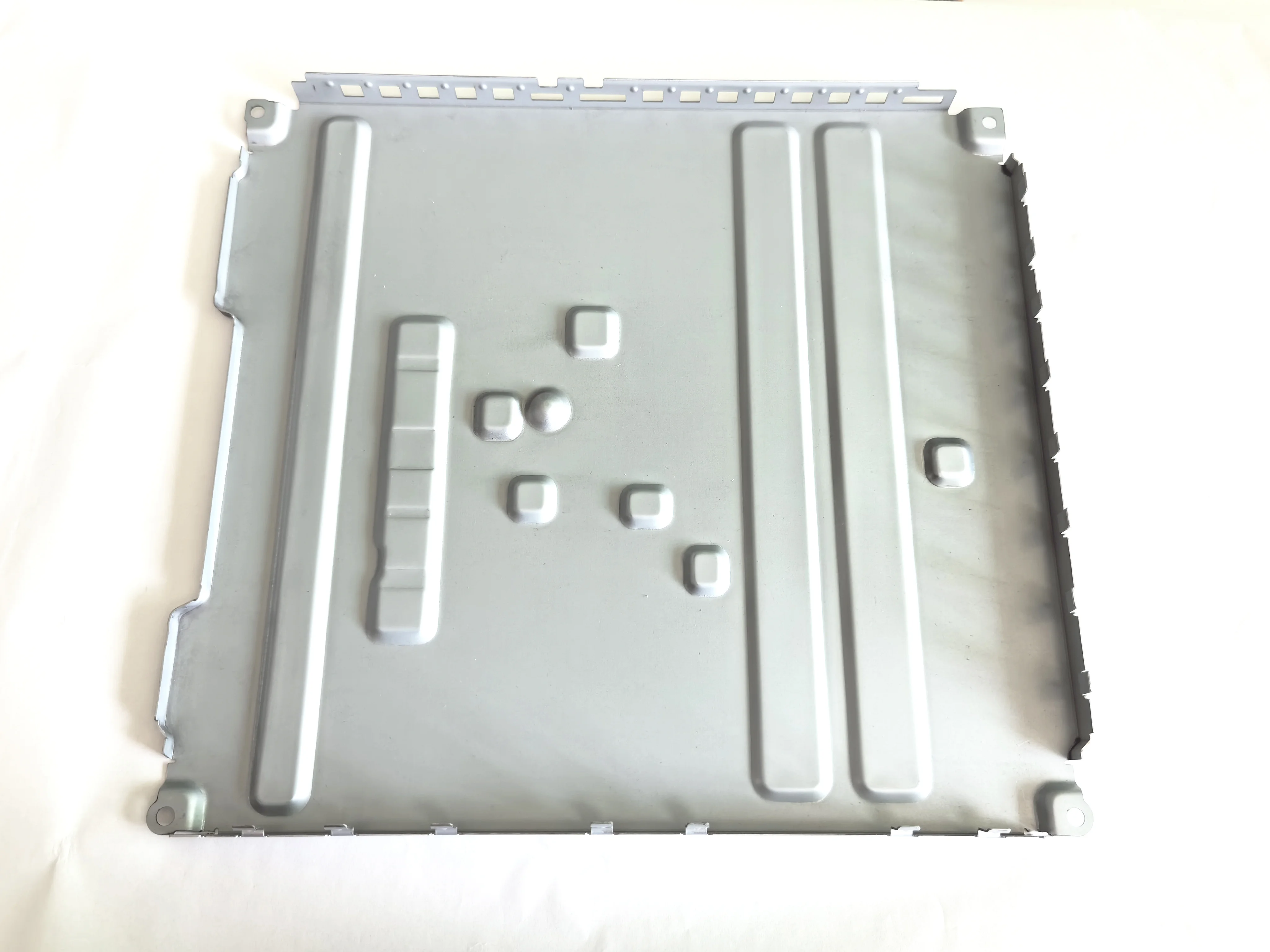

The precision of SLS prototyping stems from its layer-by-layer sintering process. The laser's precise control of energy and path enables highly accurate reproduction of complex structures and fine details. Compared to traditional CNC machining or injection molding, SLS eliminates the need for additional molds and can achieve designs such as internal channels, complex geometries, and freeform surfaces in a single molding process, significantly enhancing product design freedom and precision. For parts requiring detailed verification, SLS prototyping helps designers more intuitively identify dimensional deviations and structural defects, ensuring greater precision in subsequent mass production.

SLS also offers advantages in improving prototype strength. Common materials used, such as nylon (PA12), glass-fiber-reinforced nylon, and carbon fiber composites, exhibit excellent mechanical properties. Through appropriate material selection, SLS prototyping can not only meet cosmetic verification requirements but also withstand functional testing, such as assembly testing, impact resistance verification, and stress analysis. This reliability in strength enables SLS prototyping to more closely resemble the final product, shortening development cycles and reducing rework costs.

Optimizing design and printing parameters is also a key means of improving precision and strength. Adjusting laser power, scanning speed, and layer thickness can further enhance build quality. Furthermore, appropriate structural design, such as rib layout, optimized wall thickness, and support strategies, can effectively enhance the overall stability and load-bearing capacity of the prototype.

Looking ahead, with the development of new high-performance materials and continuous improvements in printing processes, SLS prototyping will demonstrate even greater potential in product precision and strength. It will not only meet the demands of higher-standard industrial applications but also promote product innovation and rapid iteration.

The key to improving product precision and strength using SLS prototyping lies in the effective integration of material selection, process control, and design optimization. This technology enables companies to more efficiently develop high-quality products and enhance their market competitiveness.

Related news

2025-12-10

Inquiry Hotline:

Inquiry Hotline: