- Product Detail

-

Silicone Duplication Using ABS Molds

The silicone replication process using ABS molds is a technology to replicate silicone products using molds made of ABS resin. Below are the main processes and features.

Preparation Process

Preparation of ABS molds: First, the ABS molds to be used are cleaned to completely remove dust and oil contamination from the mold surfaces. This is to ensure good mold release between the silicone and the mold.

Material Preparation: Select the appropriate silicone material and prepare the necessary curing agents and additives. Tools such as measuring equipment, mixing equipment, and de-aerators are also prepared.Duplication Process

Mixing of silicone: The silicone body and curing agent are weighed in precise proportions and mixed uniformly using mixing and kneading equipment. Care is taken to avoid air bubbles during mixing, and air bubbles are removed with a de-aerator if necessary.

Pouring into the mold: Pour the mixed and defoamed silicone into the ABS mold. When pouring, care should be taken to ensure that every corner of the mold is filled, especially in the case of complex shapes, which require slow pouring.

Curing process: Place the silicone-poured ABS mold in an environment of appropriate temperature and humidity and allow it to cure for the specified time. Curing time varies depending on the type and mix of silicone material and environmental conditions, but generally takes from several hours to several dozen hours.Post-treatment process

Mold release: After the silicone has completely cured, the silicone product is released from the ABS mold. During mold release, care is taken not to damage the mold, and if necessary, a mold release agent is used to facilitate mold release.

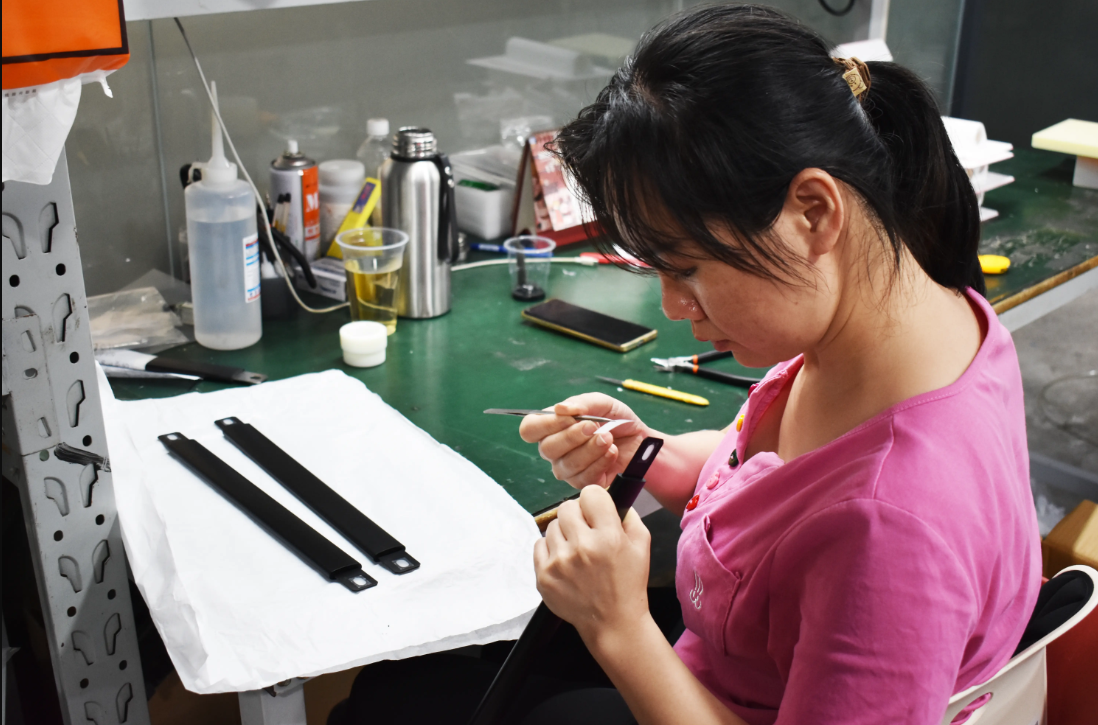

Shaping and inspection: After mold release, silicone products are shaped by removing fluff and cracks. Then, visual inspection, dimensional accuracy inspection, and physical property inspection are conducted to confirm the quality of the product.

This process is used in many fields, including automotive parts, electronics, medical devices, and toys, because it can duplicate high-precision silicone products at a relatively low cost.

ABS Mold - Silicon Rubber Casting Mold

Material: Silicon rubber Processing method: ABS mold casting Processing time: 4-5 days

Category:

Keywords:

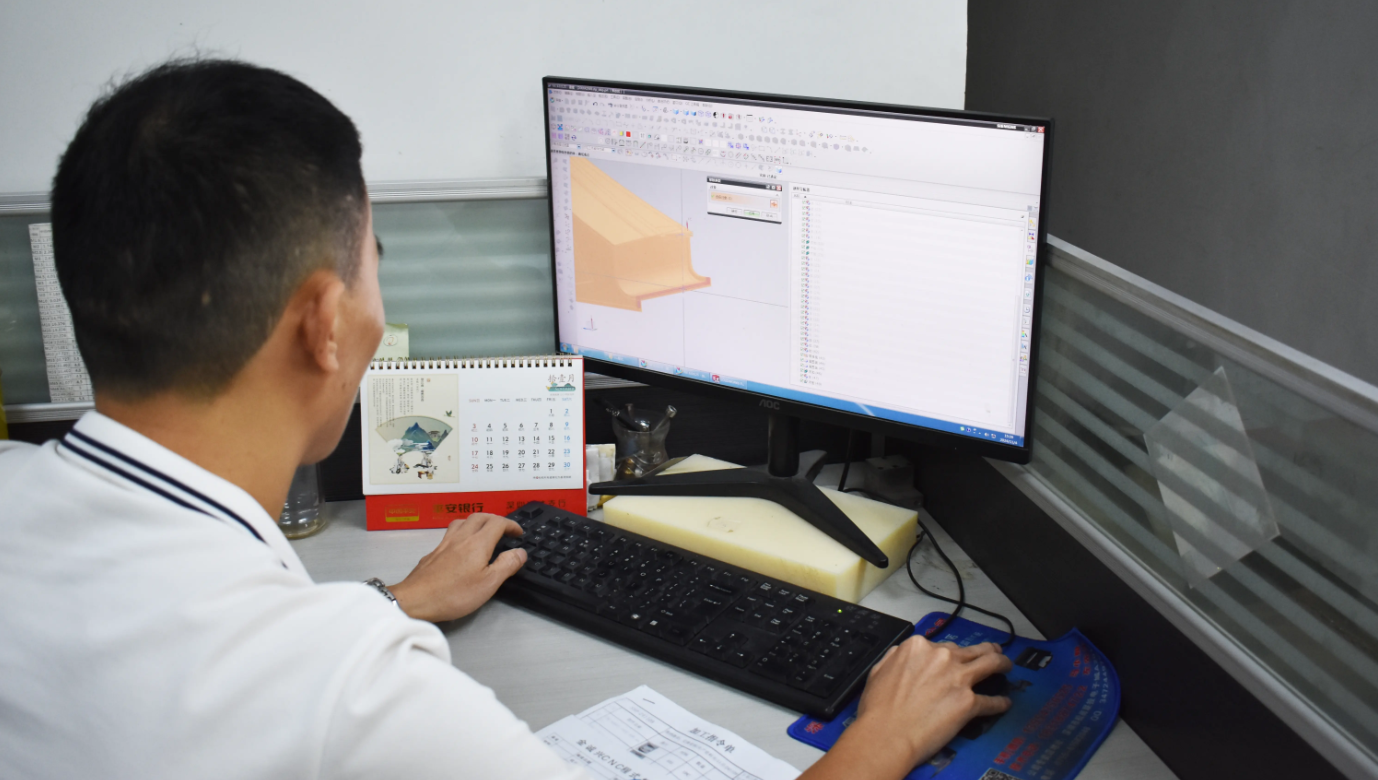

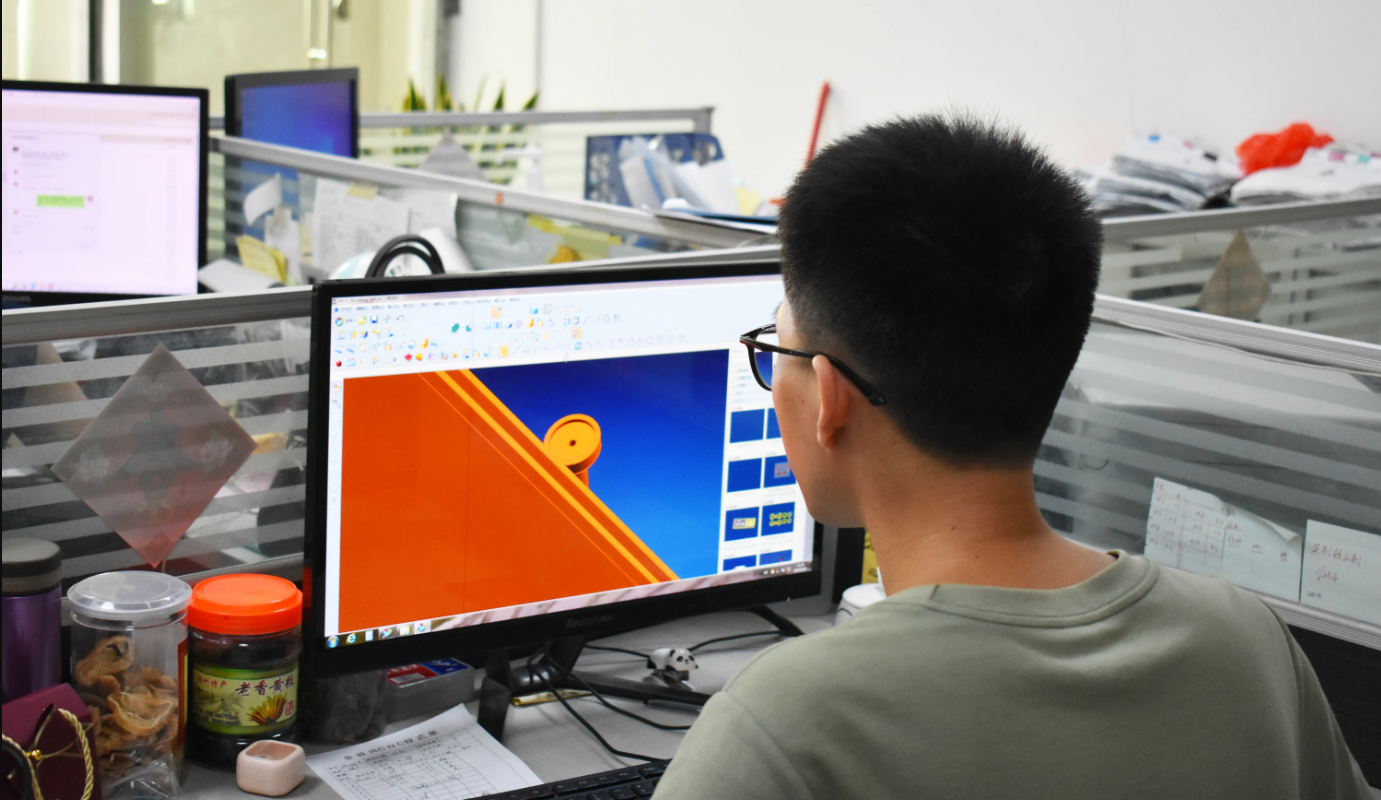

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: