- Product Detail

-

Material Selection

- To produce a plastic mockup, we select the appropriate plastic material according to the application and performance requirements. Common materials include ABS, PC, PMMA, PP, PE, PA, POM, PPS, PTFE, and PEEK. For example, ABS or PC is often selected when mechanical strength is required, while PMMA is often selected when transparency is required.

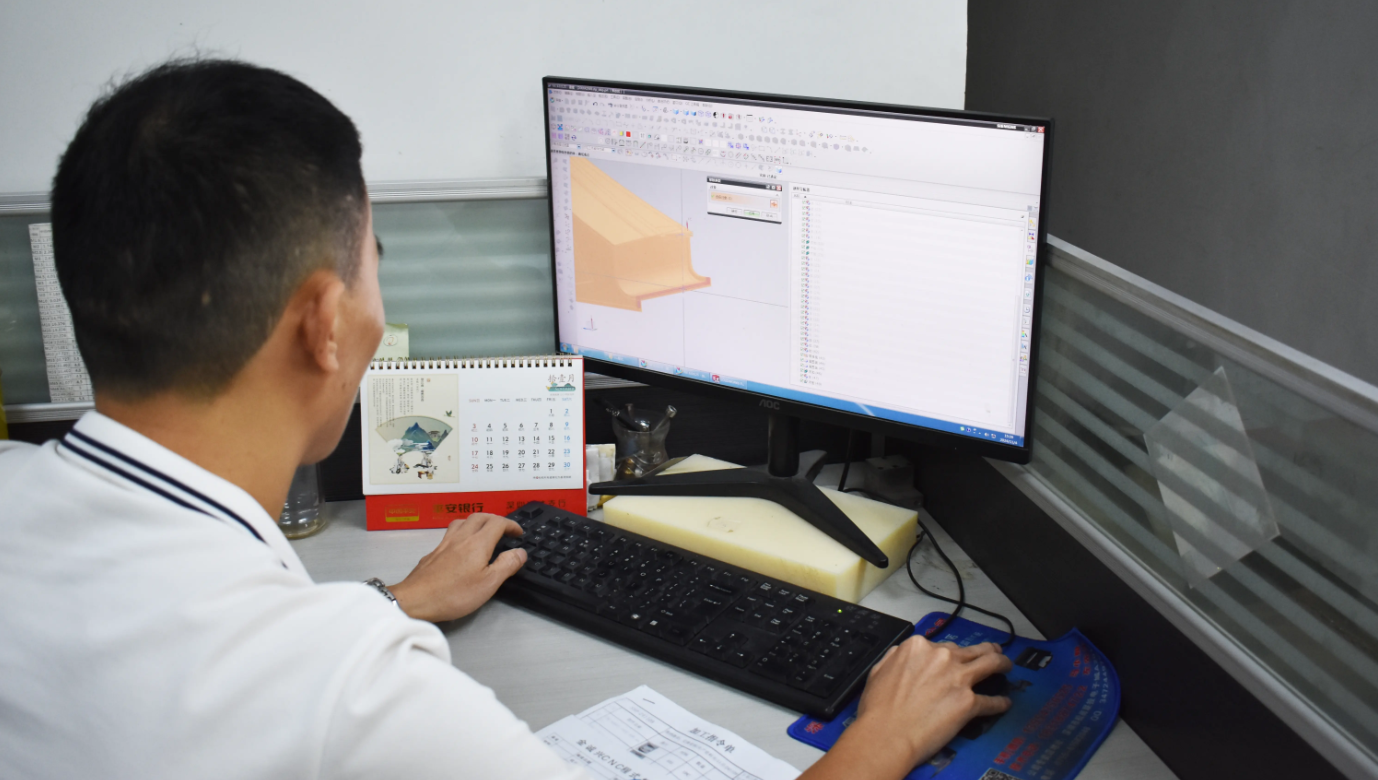

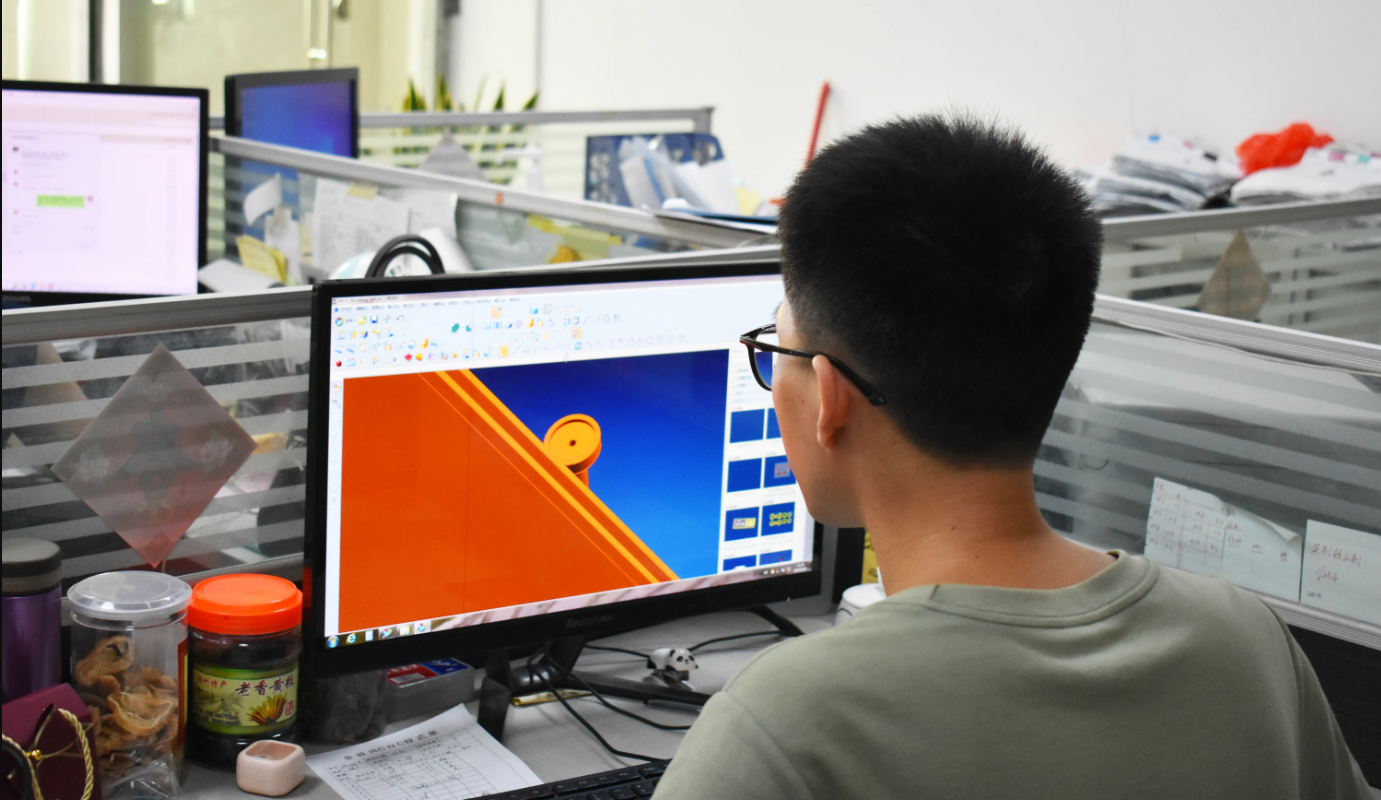

Design and CAD Modeling

- The next step is to design the product, taking into account its shape and function, and create a 3D model using CAD software. This 3D model will serve as the basis for subsequent machining processes. During the design phase, machining factors such as tolerances, slope, and wall thickness are thoroughly considered to optimize the design for ease of machining.

Cutting Machining

- High-speed engraving machine machining: High-speed engraving machines are used to cut plastic materials to form shapes. While rotating the milling end mill, the material is fed into the machine and cut into a predetermined shape. This can produce flat surfaces, depressions, grooves, holes, and other shapes.

Cutting - POM

Material: POM White Processing method: Cutting Processing time: 4-5 days

Category:

Keywords:

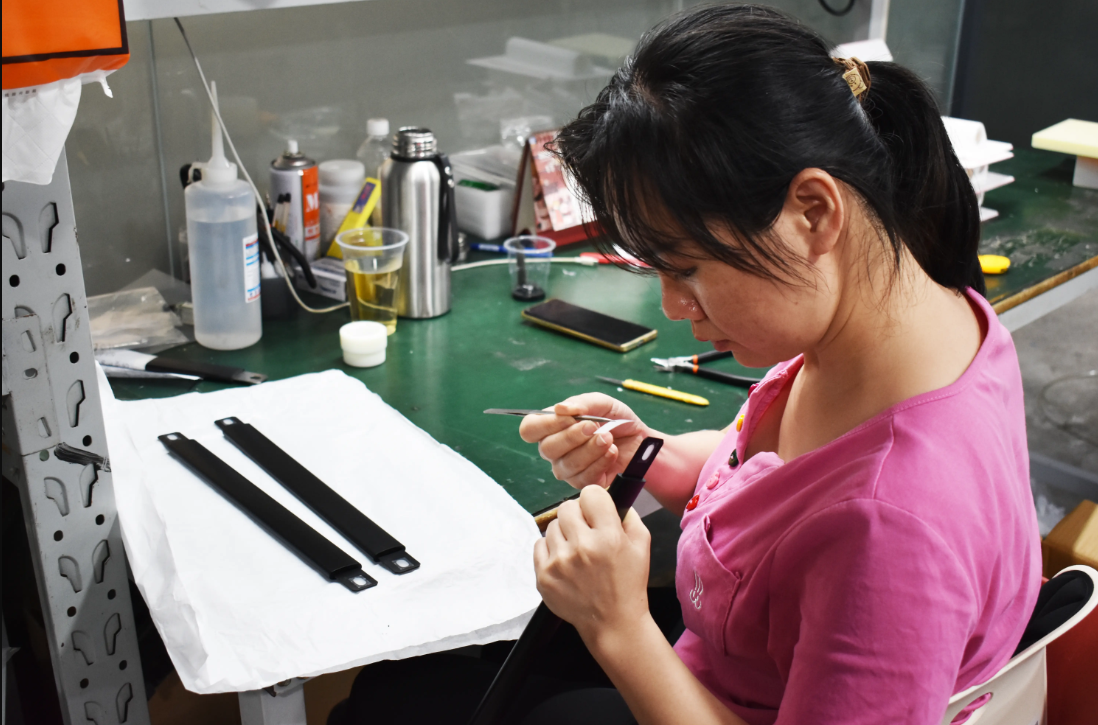

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: