- Product Detail

-

Anodizing of Aluminum Alloys Crafts

Anodizing aluminum alloys is an important surface treatment that improves corrosion resistance and decorative

corrosion resistance and decoration. The main processes are as follows

1. pretreatment

Degreasing: Remove oil and dirt from the surface of the material with an alkaline degreasing solution and wash with water.

Etching: Roughen the surface with an alkaline solution to improve the adhesion of the oxide film.

and then rinsed with water.

Desmatting: Remove impurities after etching with an acidic solution such as nitric acid, then rinse with water.

2. Anode oxidation

An aluminum alloy is used as an anode and a lead plate as a cathode in an electrolytic solution containing sulfuric acid as the main component.

An oxide film is formed on the surface. The film thickness is controlled by the current density and energization time.

3. coloring (optional)

Dye coloring: Swell the film with warm water, immerse in dye solution to color, and wash with water.Electrolytic coloring: Electrolysis in an electrolytic solution containing metallic salts causes metallic ions to precipitate in the pores of the film, resulting in coloring.

Electrolytic coloring: Color is produced by passing an electric current through an electrolytic solution containing metal salts to deposit metal ions in the pores of the film.

4. sealing

Steam sealing: The pores of the coating are sealed in high-temperature steam to improve corrosion resistance.

Hot water sealing: Pores are sealed by immersion in hot deionized water or water containing a pore accelerator.

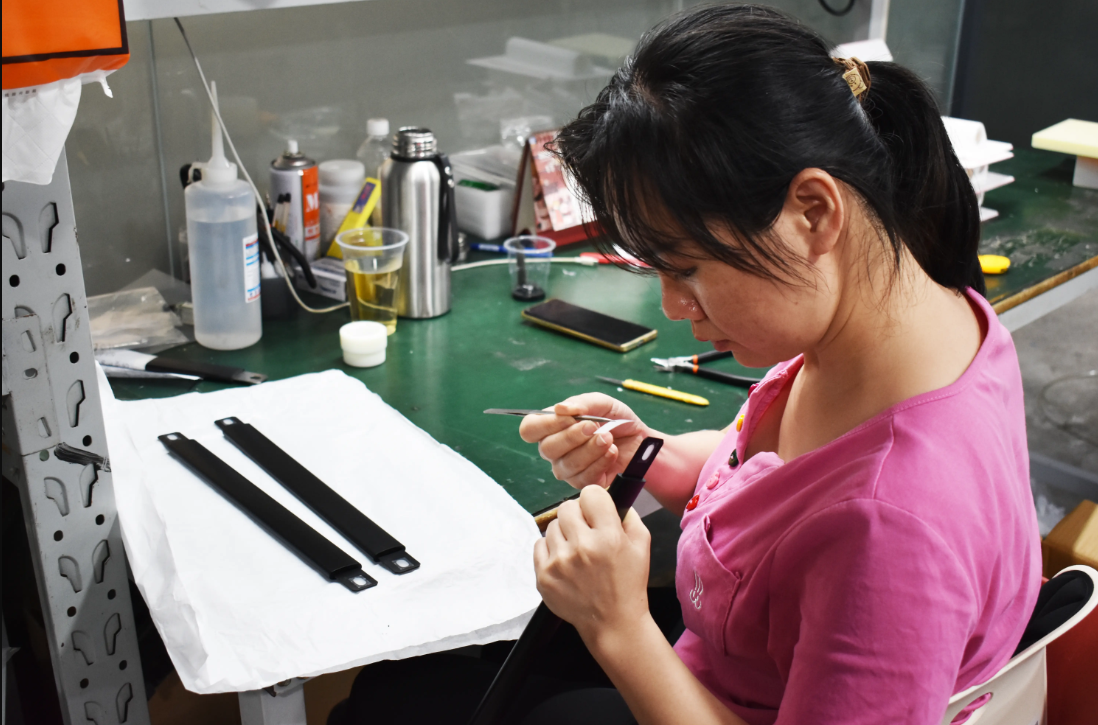

5. post-treatment

Surface contamination is removed by rinsing with water, and the surface is dried naturally or by warm air drying.

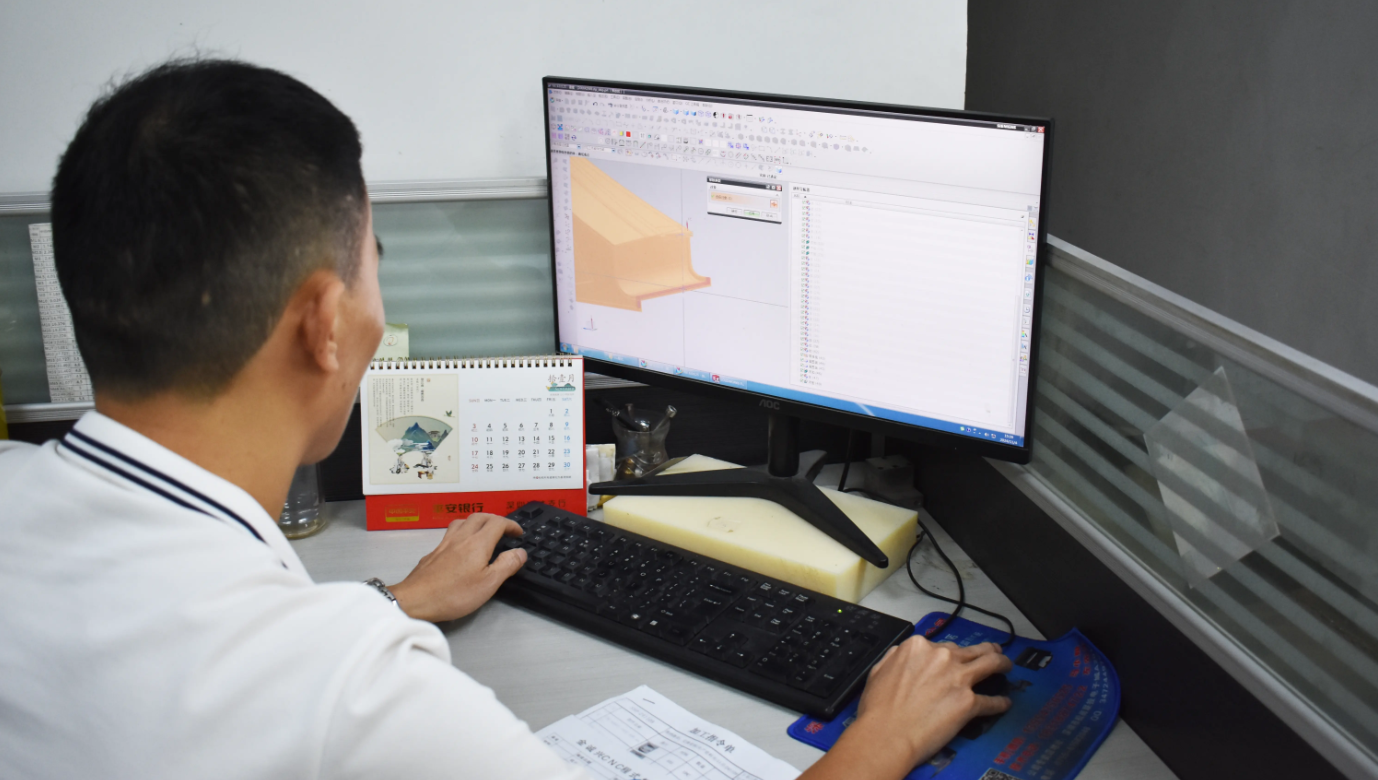

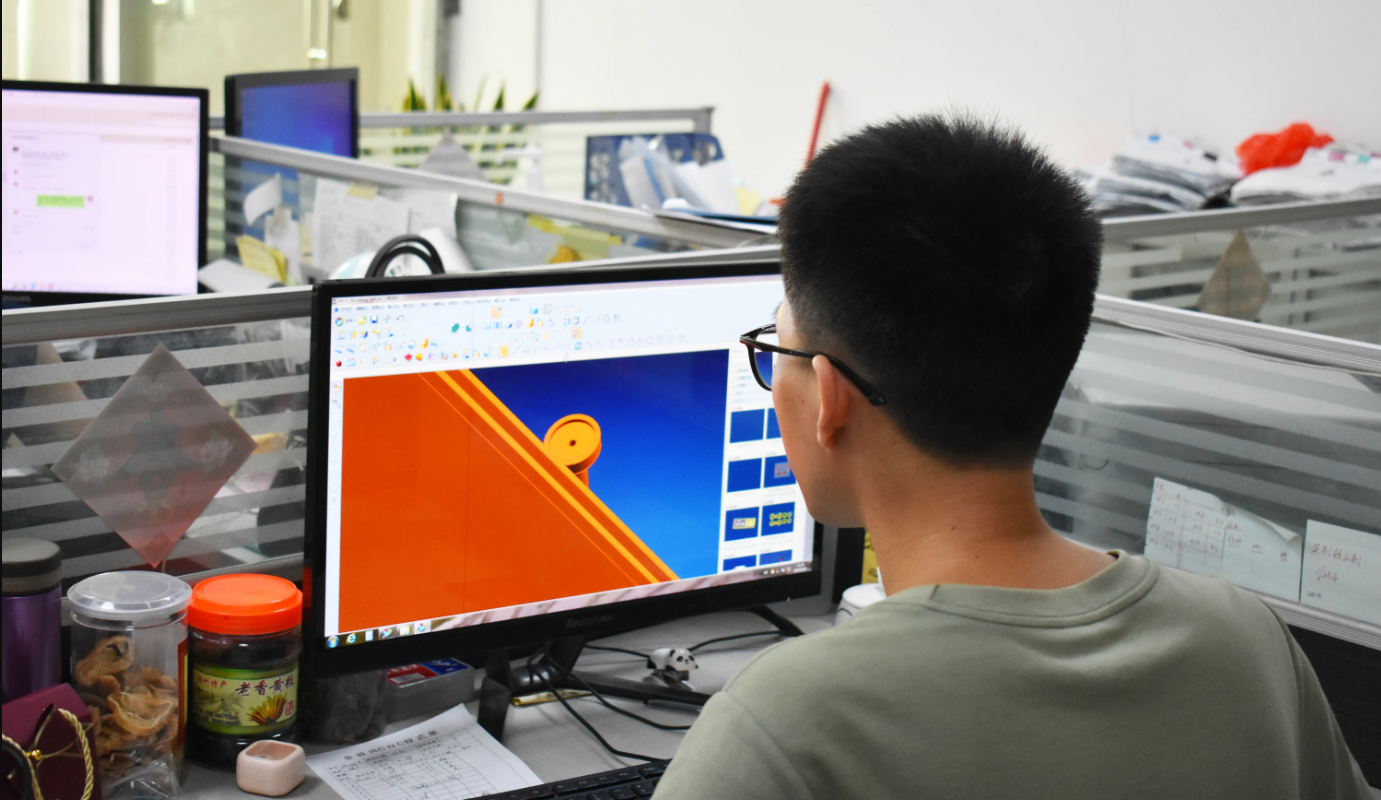

Aluminum cutting + alumite treatment

Material :AL Processing method :Cutting + Alumite treatment Processing time: 5-7 days

Category:

Keywords:

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: