- Product Detail

-

In the metalworking industry, electropolishing technology, with its superior performance and widespread application, has become a key process for improving the quality of metal products.

Principles and Advantages

Electropolishing is an electrochemical surface treatment process. In a specific electrolyte, an electric current preferentially dissolves microscopic protrusions on the metal surface, resulting in a smooth, shiny finish. Compared to traditional mechanical polishing, electropolishing offers many significant advantages. It can process complex metal parts without the surface damage and deformation that can occur with mechanical polishing. Electropolishing significantly reduces surface roughness and significantly improves surface smoothness, achieving a mirror-like finish.

Improves Corrosion Resistance

Electropolishing not only enhances the aesthetics of metal surfaces but also effectively enhances their corrosion resistance. During the treatment, a dense passivation film forms on the metal surface. This film acts like a strong armor, protecting against environmental corrosion and extending the service life of the metal product. Electropolished metal parts maintain excellent performance in environments ranging from humid marine environments to corrosive chemical production plants.

Wide Range of Applications

Electropolishing technology has a wide range of applications. In the medical device industry, it can smooth the surface of surgical instruments, reduce bacterial adhesion, and improve instrument hygiene standards. In the food processing industry, electropolished equipment and containers are easy to clean and meet strict hygiene requirements. In electronic equipment manufacturing, it can improve the conductivity and heat dissipation of metal parts. Furthermore, in industries such as jewelry and architectural decoration, electropolishing can add a unique gloss and texture to products.

Environmental Protection and Energy Saving

Our electropolishing process focuses on environmental protection and energy conservation. Using advanced electrolyte formulas and optimized process flows, we reduce chemical use and waste emissions. Furthermore, lower energy consumption reduces production costs, aligning with the concept of sustainable development.

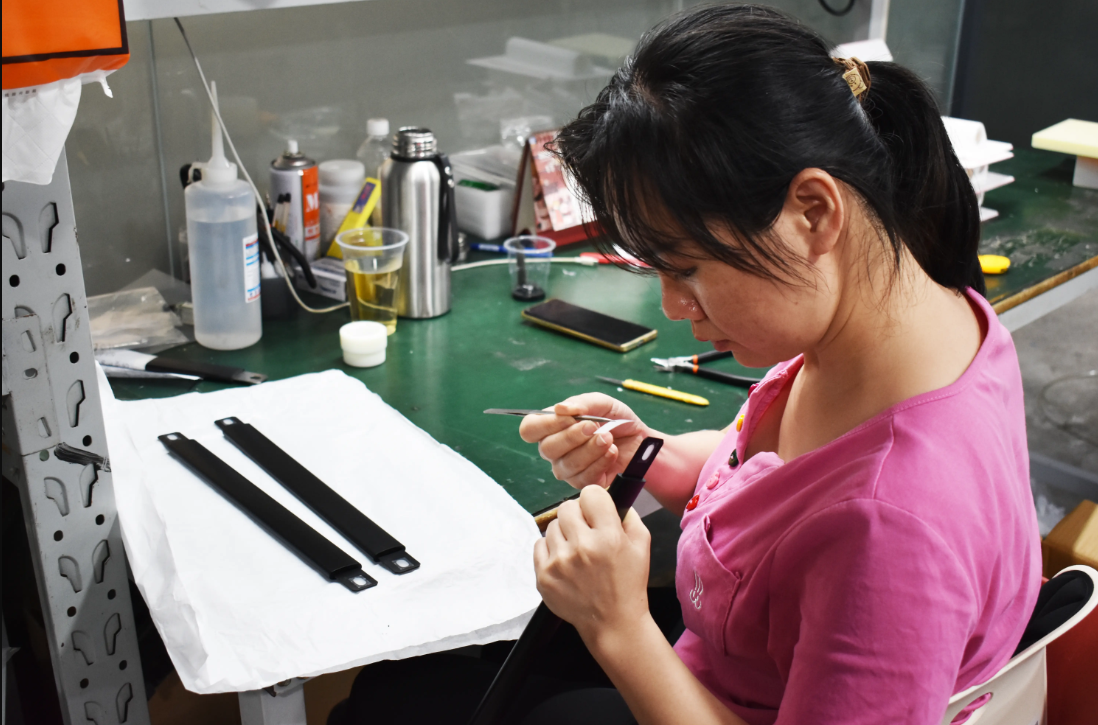

Cutting + Painting + Printing

Material Plastic Processing method Spray + Print Processing time: 5-7 days

Category:

Keywords:

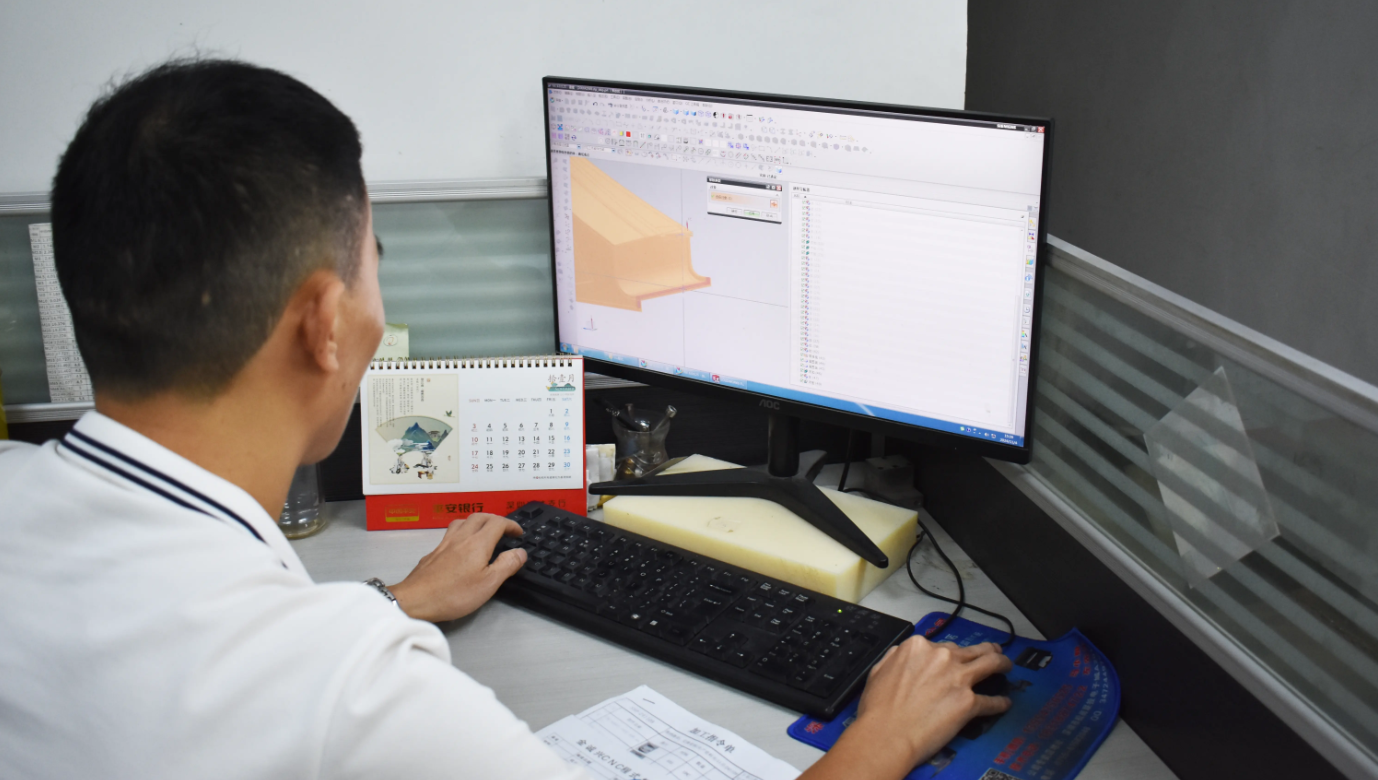

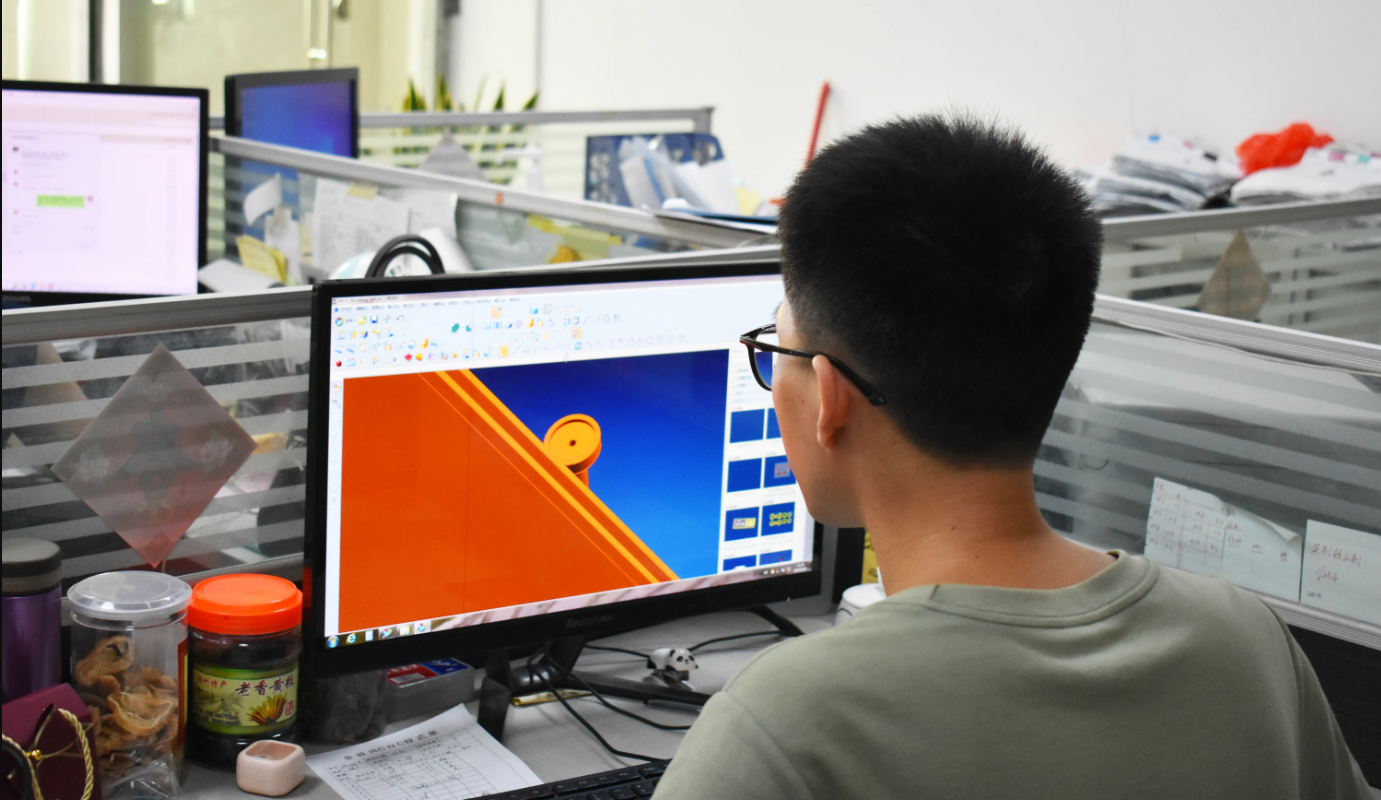

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: