- Product Detail

-

Bending of Hardware Bars

Metal bar bending is a process for bending metal bars into desired shapes and is widely used in many industrial fields. The following are the main contents of this process.

Processing Method

Cold bending: Bending bars at room temperature. Mainly, a press or bending machine is used to bend bars by placing them against a die. This method has the advantages of high accuracy and minimal surface scratches. It is also suitable for processing parts that require strength and hardness because the mechanical properties of the bar material do not change easily after processing.

Hot bending: This method bends bars after heating and softening them. In general, bars are heated using a gas burner or electric furnace, and bending is performed once they reach a predetermined temperature. Hot bending is advantageous when bending large-diameter or high-strength bars and can reduce the bending radius, but may result in a larger surface roughness after processing.Machining Process

Material Preparation: First, hardware bars suitable for processing are selected, and if necessary, cut and adjusted to the specified length. The bar surfaces are also polished to remove scratches and rust to improve the accuracy of the bending process.

Bending: For cold bending, bars are set in a press or bending machine and bent according to preset molds and parameters. In the case of hot bending, bars are first heated in a heating facility and then bent in a bending machine under strict temperature control. During processing, the bending angle and radius are constantly monitored to ensure accuracy.

Post-processing: After bending, the bar surface is cleaned to remove chips and oil stains. In addition, tempering and other treatments are performed as necessary to remove processing stress and stabilize the bar's mechanical properties. Finally, visual and dimensional accuracy inspections are performed to confirm the quality of the product.

Bending metal bars is an essential process in the manufacture of many products, including automotive parts, construction machinery, and electrical equipment, and greatly affects the function and performance of the product.

warp process

Material :SUS Processing method: Bending Processing time: 5-7 days

Category:

Keywords:

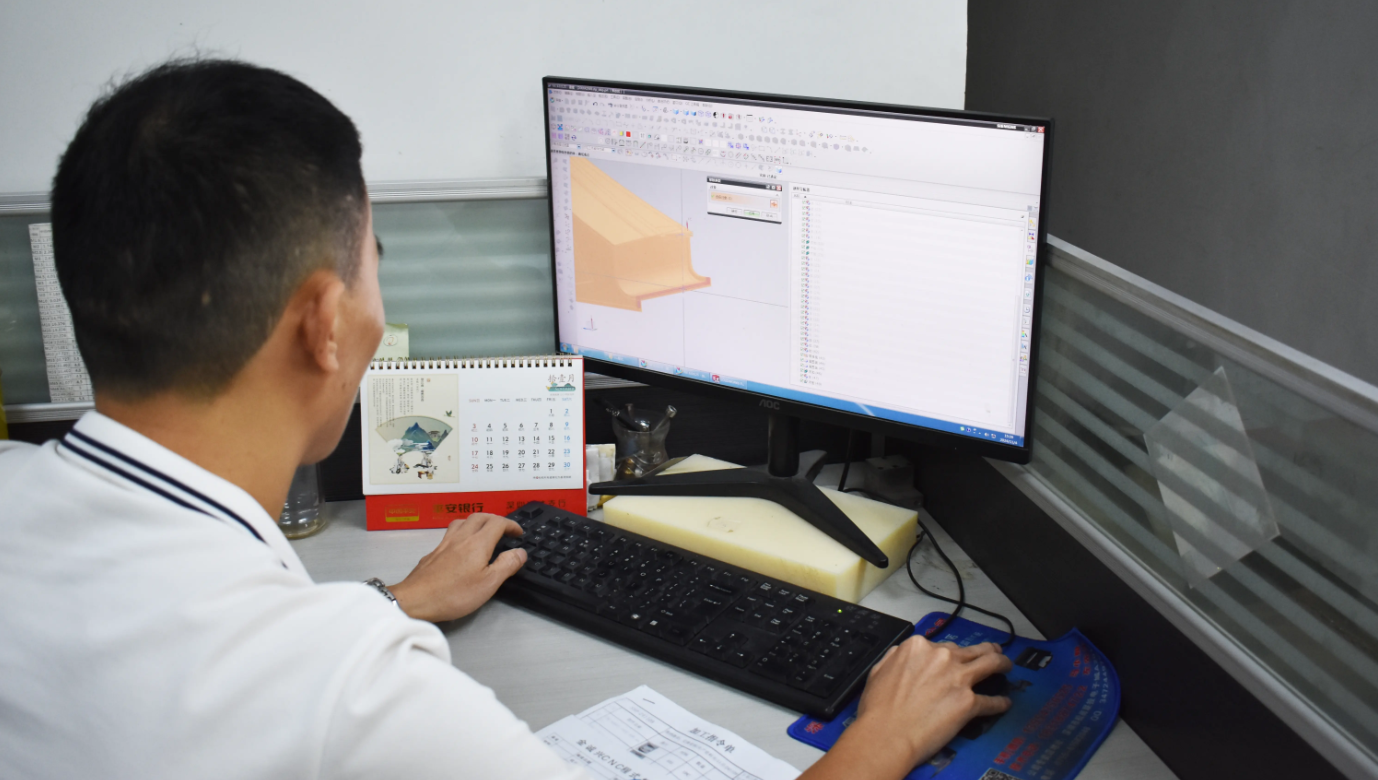

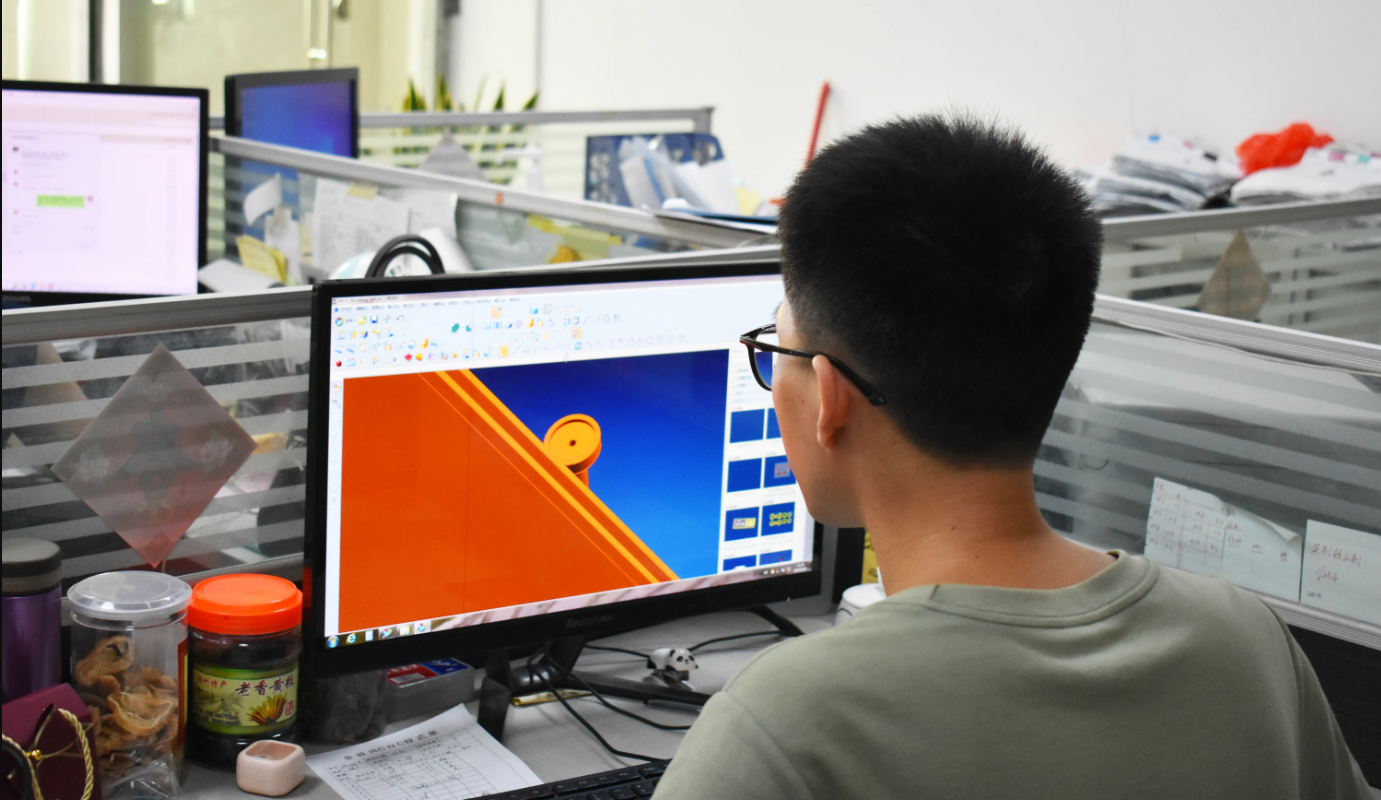

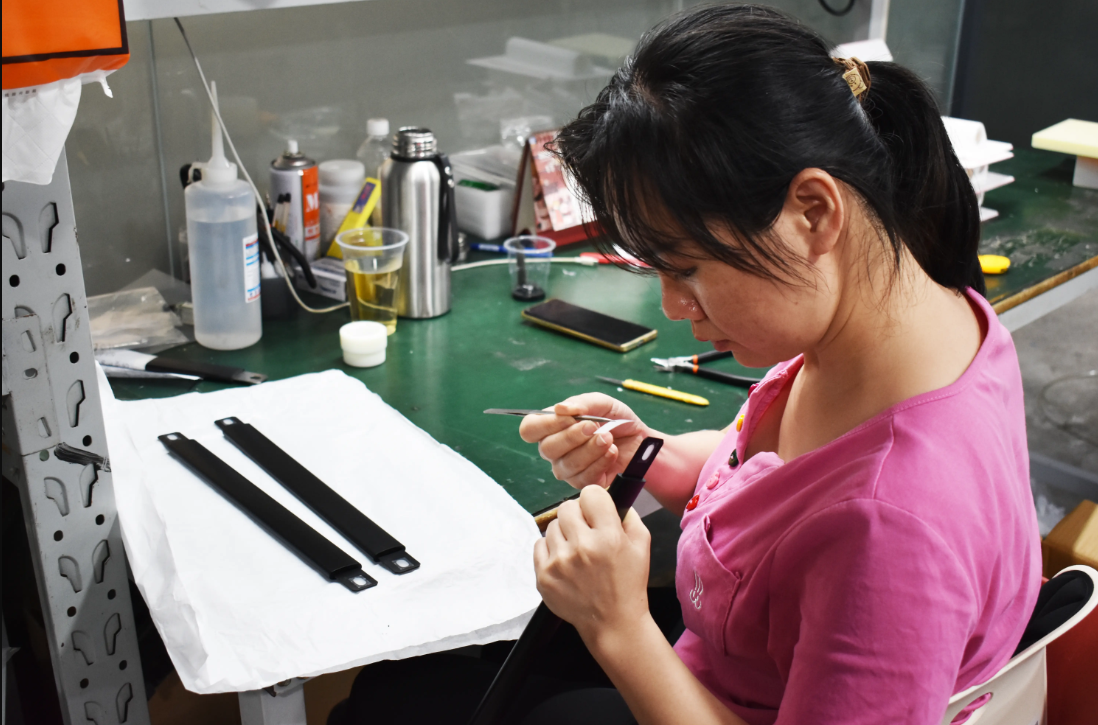

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: