- Product Detail

-

Metal cutting is a method of machining metal materials using computer numerical control (CNC) technology.

CNC technology to process metal materials.The main features and machining operations are as follows

High accuracy and repeatability: CNC equipment precisely controls the machine tool based on a pre-input program, enabling highly accurate machining.

High-precision machining is possible because the CNC system precisely controls the machine tools based on a pre-input program. The same program can be run repeatedly to ensure the same quality and repeatability.

The same program can be run repeatedly to consistently produce parts of the same quality and accuracy.

Ability to machine complex shapes: CNC machines with multi-axis control based on 3D CAD data can be used to machine complex curved surfaces and three-dimensional shapes.

CNC machines with multi-axis control based on 3D CAD data, etc., can accurately machine complex curved surfaces and three-dimensional shapes of alloy parts. For example, the head block of an automobile engine or the head block of an aircraft can be accurately machined.

For example, head blocks of automobile engines and wing parts of aircrafts.

Various machining methods

CNC turning: CNC lathes are used to control the cutting tool while rotating the workpiece,

CNC turning: CNC turning machines are used to process cylindrical parts with high precision by controlling the cutting tool while rotating the workpiece.

CNC milling: Using a CNC milling machine, a rotating milling blade is controlled in three or more directions to produce flat, grooved, or flat parts.

CNC milling: CNC milling machines are used to machine various shapes such as flat surfaces, grooves, gears, and depressions by controlling the rotating milling blades in three or more directions.

CNC Milling: Based on a 3D model, a multi-axis CNC milling machine is used to cut complex vertical shapes.

CNC milling: Based on 3D models, complex vertical shapes are machined using a multi-axis CNC milling machine.

Increased production efficiency: Automated machining process minimizes human error and ensures continuous machining.

Automated machining processes minimize human error and allow continuous machining. Functions such as a tool changer allow different machining operations to be performed efficiently.

different machining operations efficiently.

CNC machining of hardware is widely used in the automotive, aerospace, and electronics industries.

It is an important machining method for the mass production of high-precision, complex

It is an important method for the mass production of high-precision, complex-shaped alloy parts.

Metal cutting

Material : AL Processing method : Cutting Processing time : 5-7 days

Category:

Keywords:

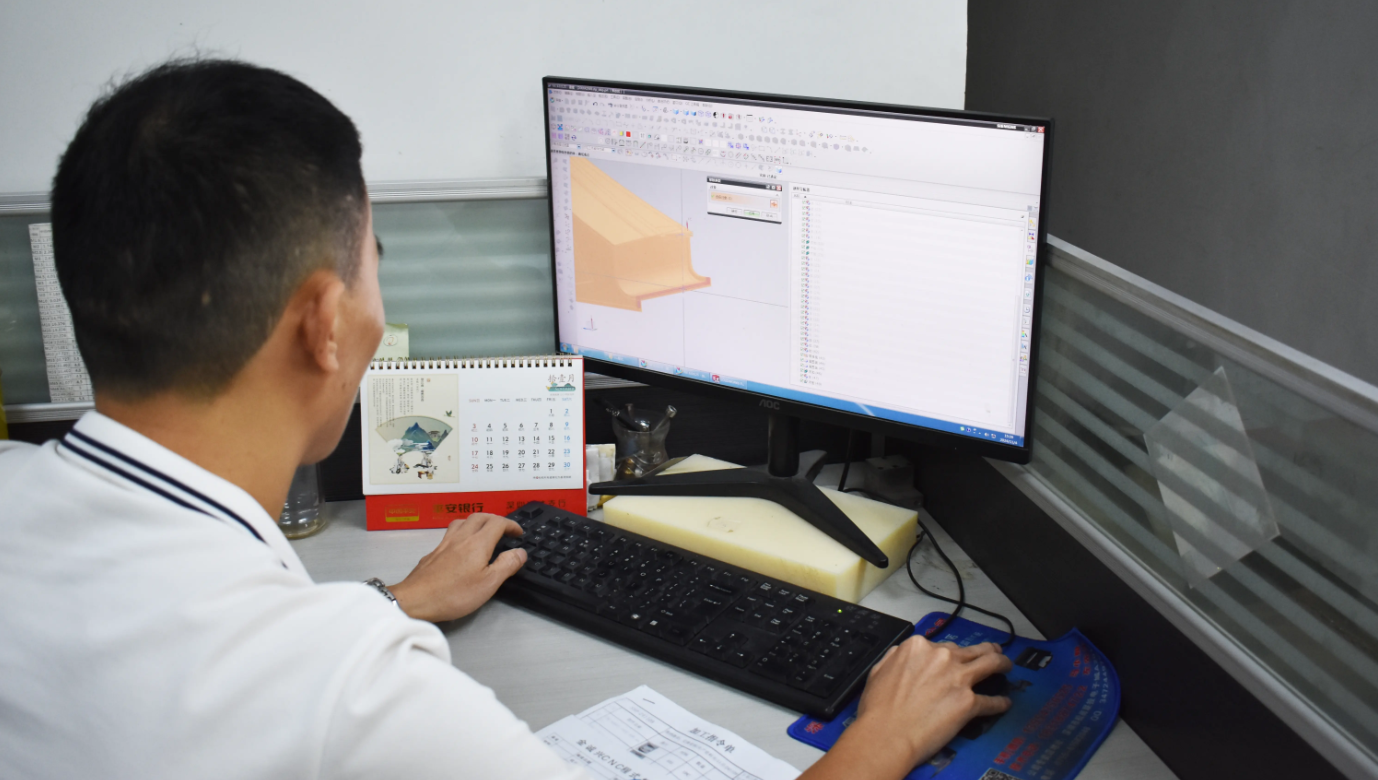

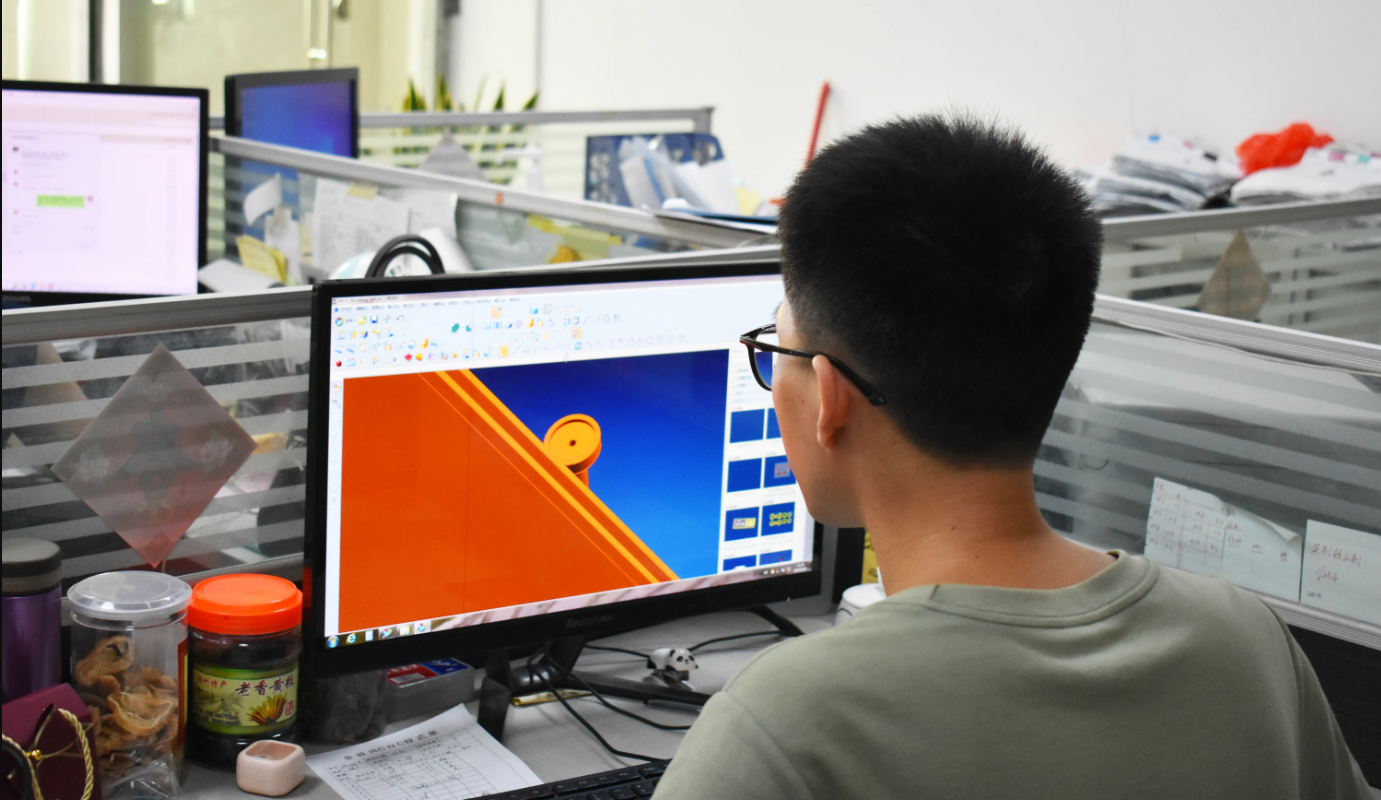

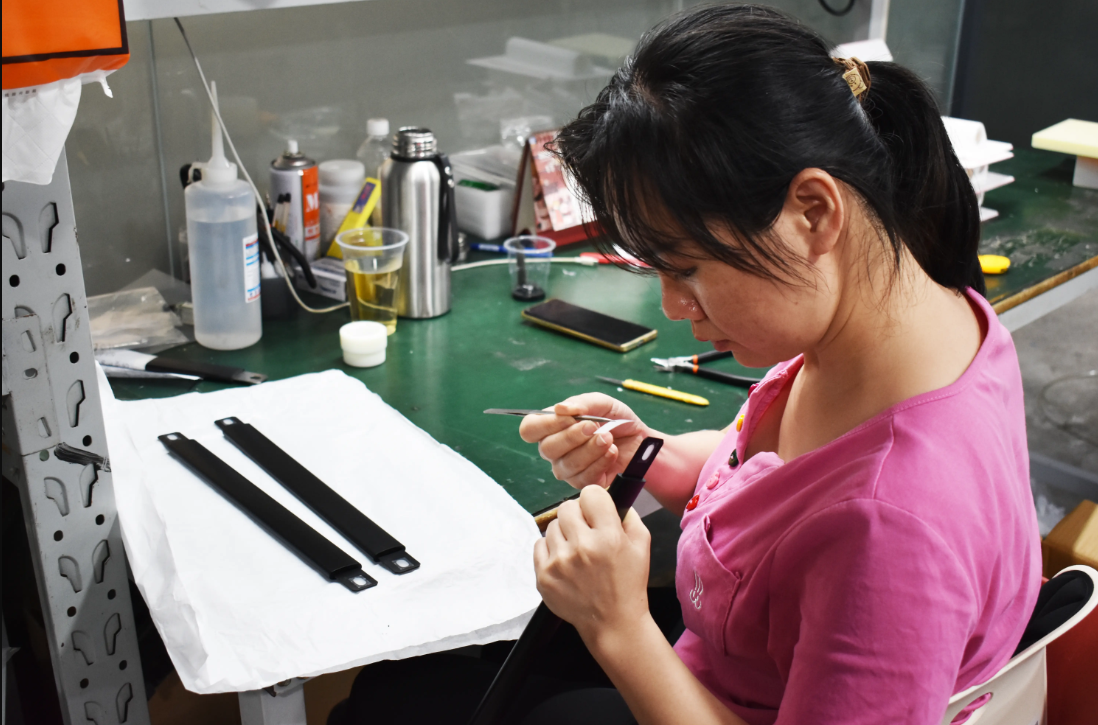

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: