- Product Detail

-

Solid State Laser Array (SLA)

Principle: Light such as ultraviolet light is irradiated to create three-dimensional objects by curing and layering light-curing resins one layer at a time. Typically, the light pattern is controlled using an LCD panel or DLP (digital light processing) device.

Characteristics: Because it can reproduce highly precise and detailed shapes, it is suitable for modeling art works and creating prototypes for precision machine parts. However, the materials are comparatively expensive and the devices can be large and expensive.

Selective Laser Sintering (SLS)

Principle: Metal and plastic powders are selectively sintered and layered using laser beams. The powder material is first laid down uniformly, the laser beam is irradiated to sinter a specific area, and the same operation is repeated with the next layer of powder.

Feature: Parts with complex internal structures can be made. Since metallic materials can also be used, it can be used for direct manufacturing of mechanical parts. However, precision control can be difficult due to thermal distortion caused by the sintering process.

powder metallurgy

Material: Nylon-like powder Processing method: Powder molding Processing time: 5-6 days

Category:

Keywords:

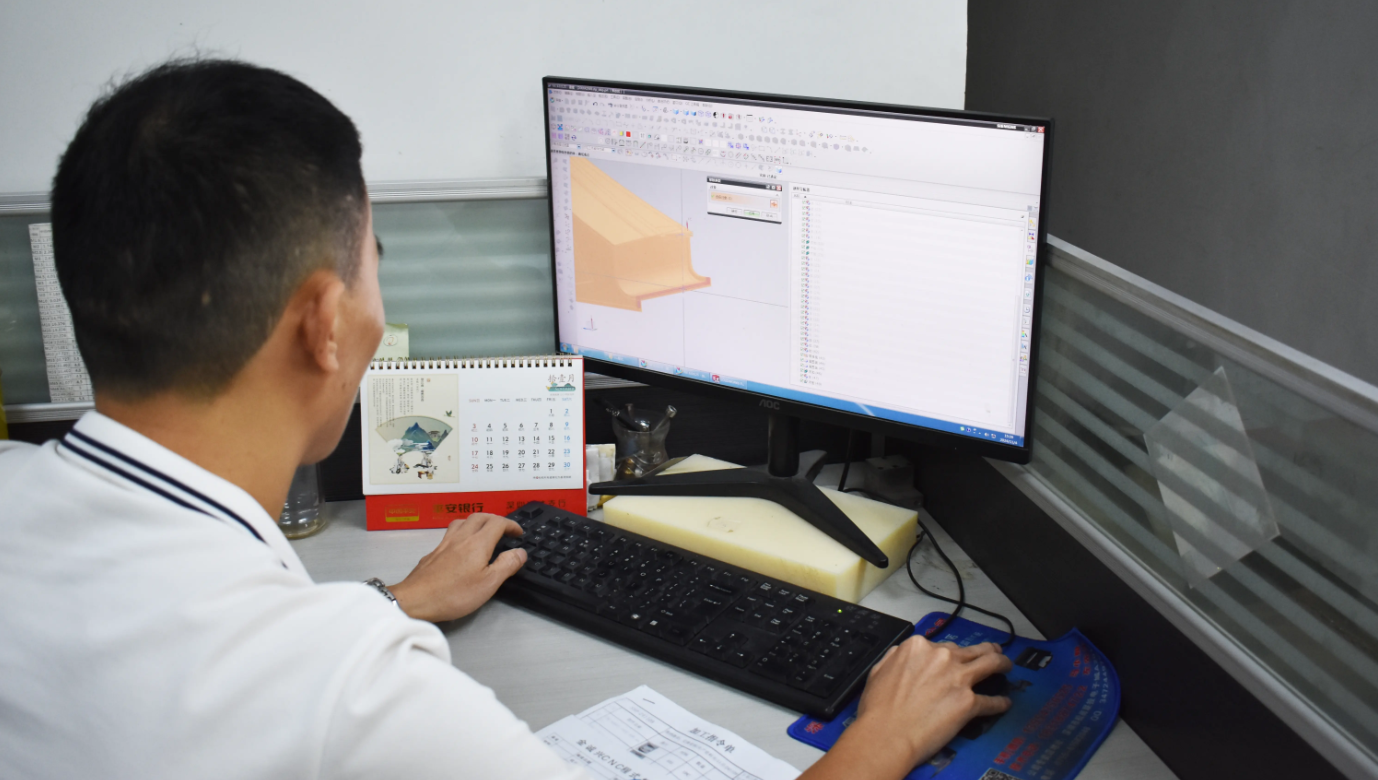

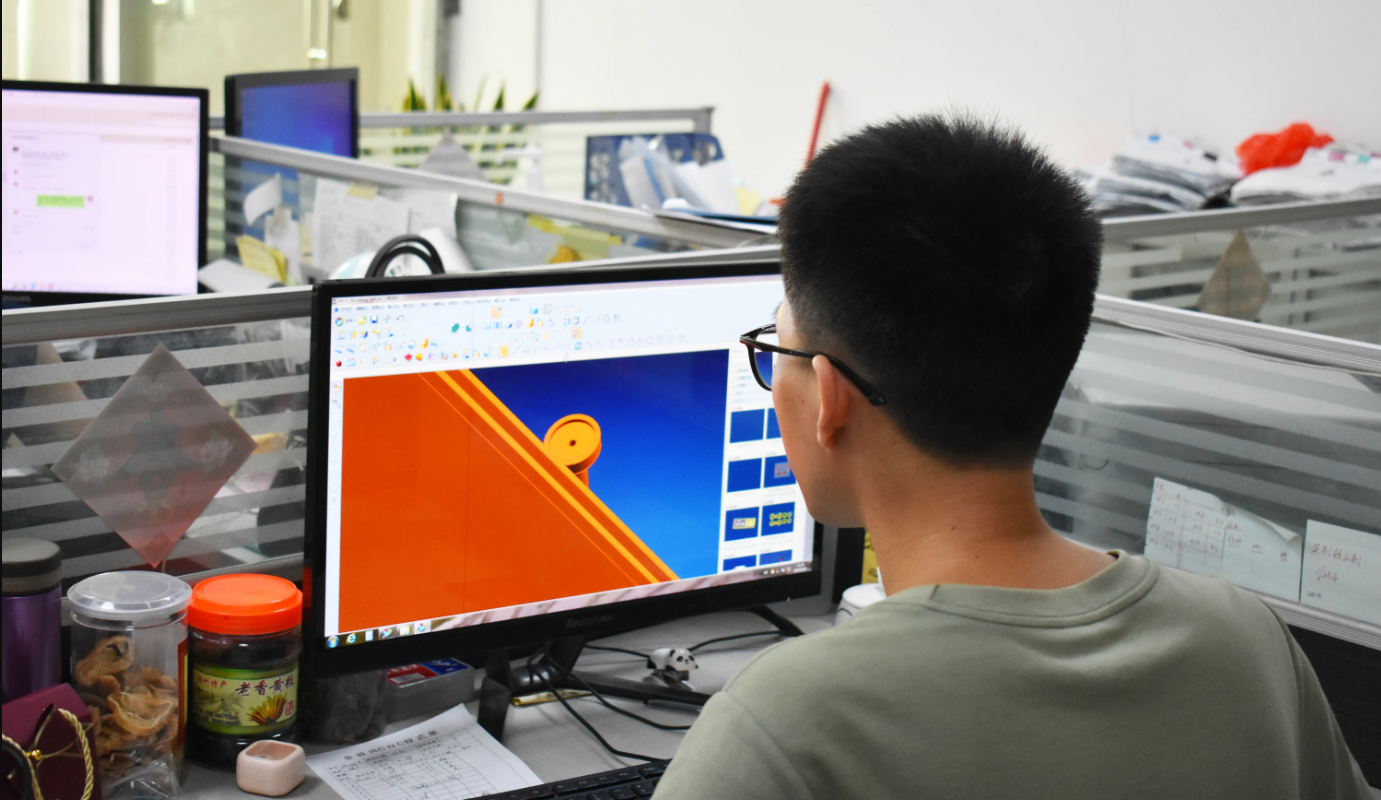

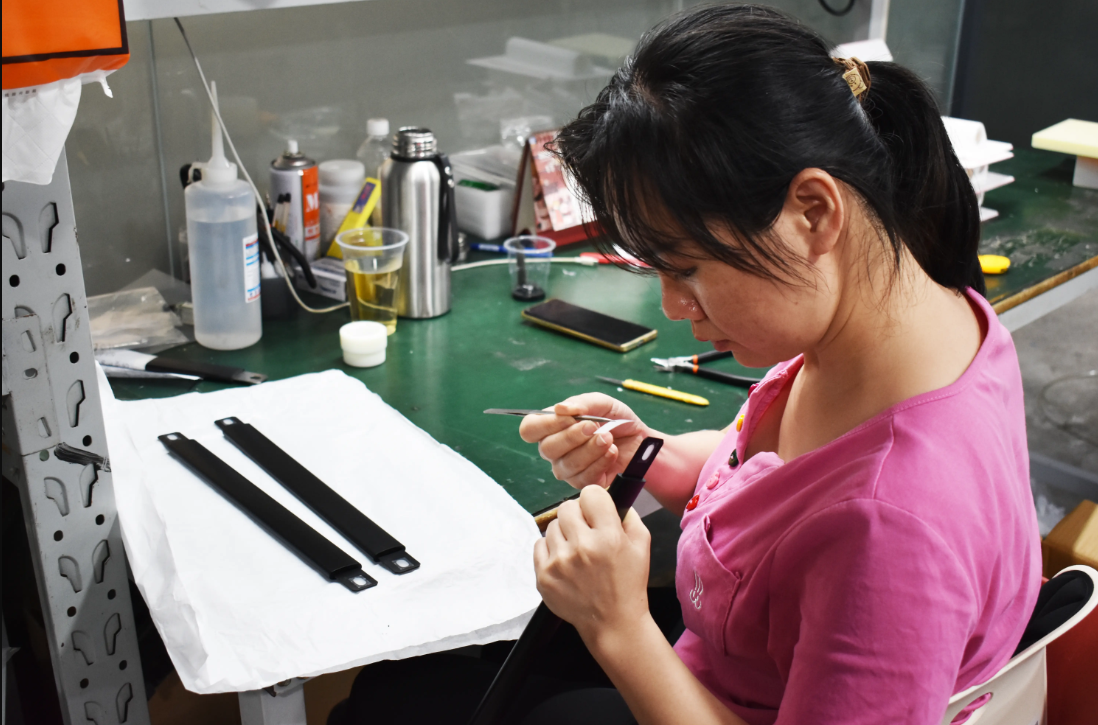

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: