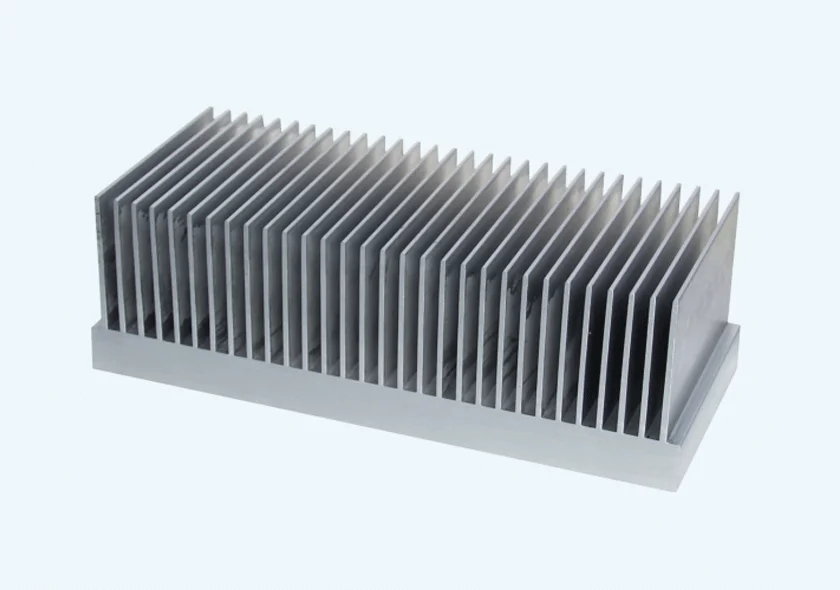

- Product Detail

-

Wire EDM (wire-cut EDM) is a cutting technology in which a high-frequency pulse current is passed through a wire-shaped electrode, and the discharge energy generated between the wire and the workpiece melts and vaporizes the workpiece. Below is an explanation of its features and application fields.

Features

High-precision machining: The small wire diameter enables extremely high-precision machining. Accuracy of ±0.01mm can be achieved, making it suitable for machining small parts.

Complex shape machining: The wire can be controlled and machined into any desired shape, facilitating the machining of parts with complex contours and curved surfaces.

Material adaptability: Even high-hardness and high-strength materials can be processed. For example, it is an effective tool for machining tool steel and cemented carbide.

Low machining stress: Since no cutting force is applied, machining stresses are low and part deformation can be reduced.Fields of Application

Die manufacturing: Widely used for precision mold hole machining of plastic molding dies, forging dies, etc.

Electronic parts manufacturing: Suitable for machining micro parts such as semiconductor packages and IC carriers to achieve high-precision shapes.

Automotive parts: It is also used in the machining of automotive drivetrain parts, brake parts, etc., and can process high-strength materials with high precision.

Wire EDM has become an important processing technology in many fields where precision processing is required.

Aluminum Wire Cut is an efficient tool designed for cutting aluminum wire.

Structurally, Aluminum Wire Cut has a sturdy and durable body that can adapt to long-term cutting work. Its cutting part is made of high-quality alloy material with high hardness and wear resistance to ensure cutting accuracy.

In terms of cutting capacity, it can easily cope with aluminum wires of different diameters. Whether it is thinner aluminum wire or thicker aluminum wire, it can achieve a smooth and neat cutting effect, with a flat incision without burrs or deformation.

It is very convenient to operate, and the design conforms to ergonomic principles, making it easy to hold and operate. At the same time, Aluminum Wire Cut is also equipped with a safety protection device to avoid accidental injuries during the cutting process.

This aluminum wire cutting product is widely used in electronic manufacturing, wire processing and other industries. With its high efficiency, precision and safety, Aluminum Wire Cut provides a reliable solution for aluminum wire cutting work, effectively improving production efficiency and reducing material waste.

Aluminum Wire Cut

Material: Aluminum Processing method: Wire cutting Processing time: 6-7 days

Keywords:

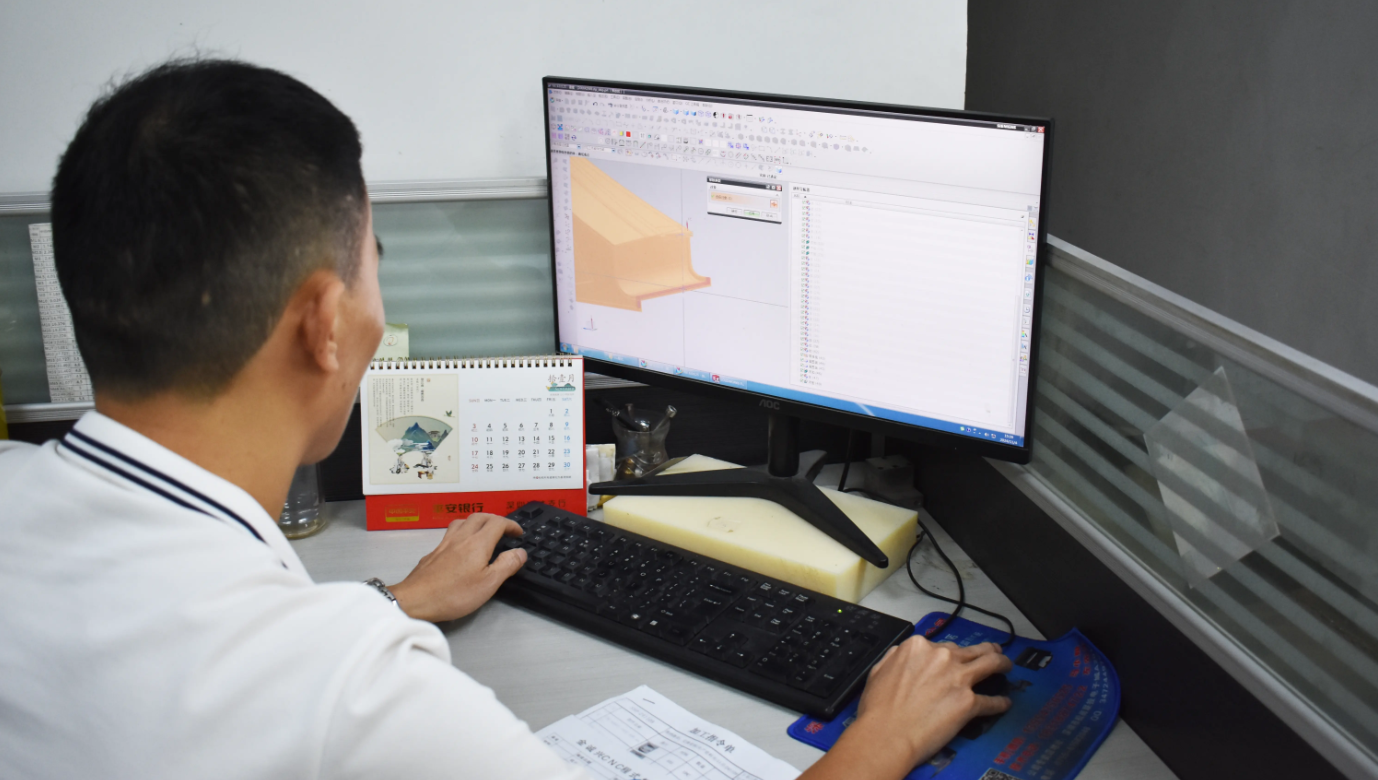

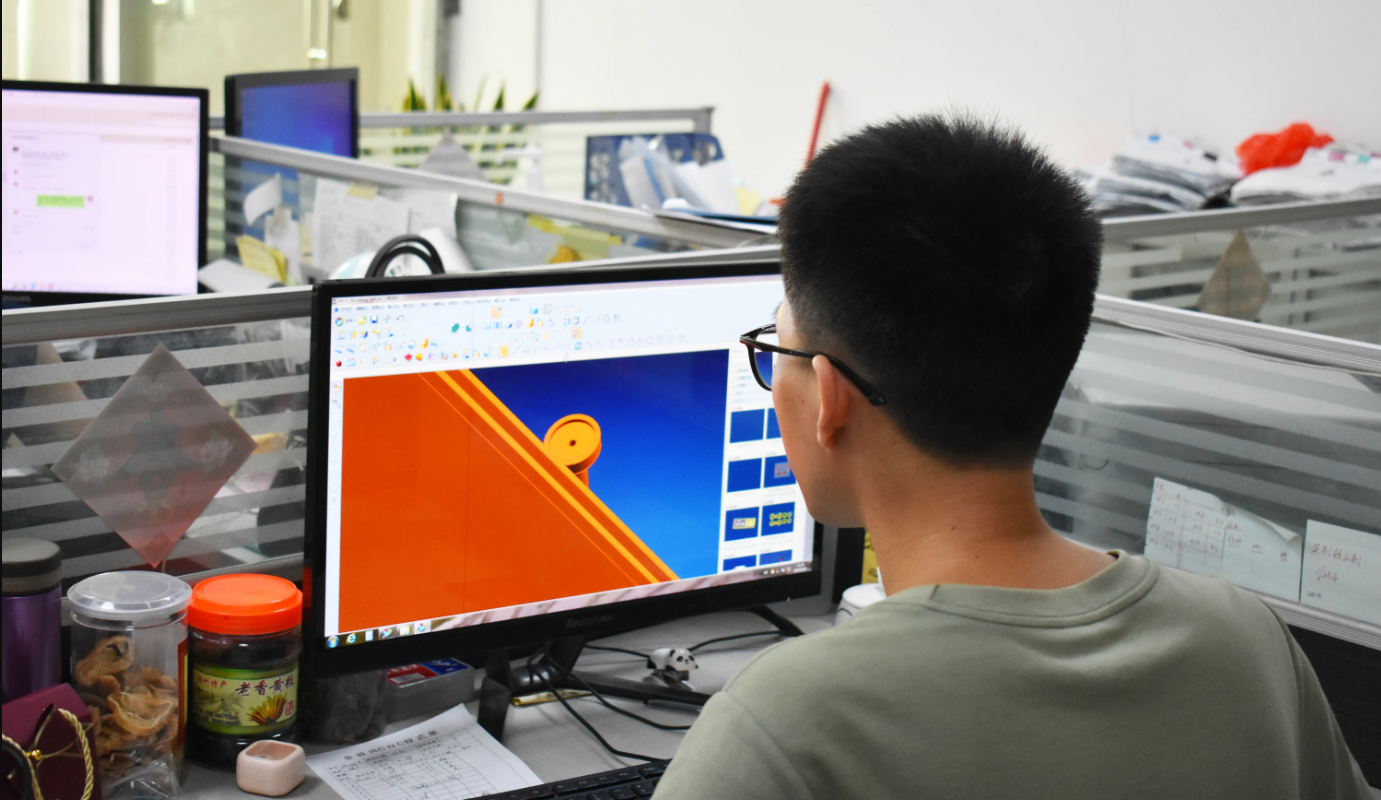

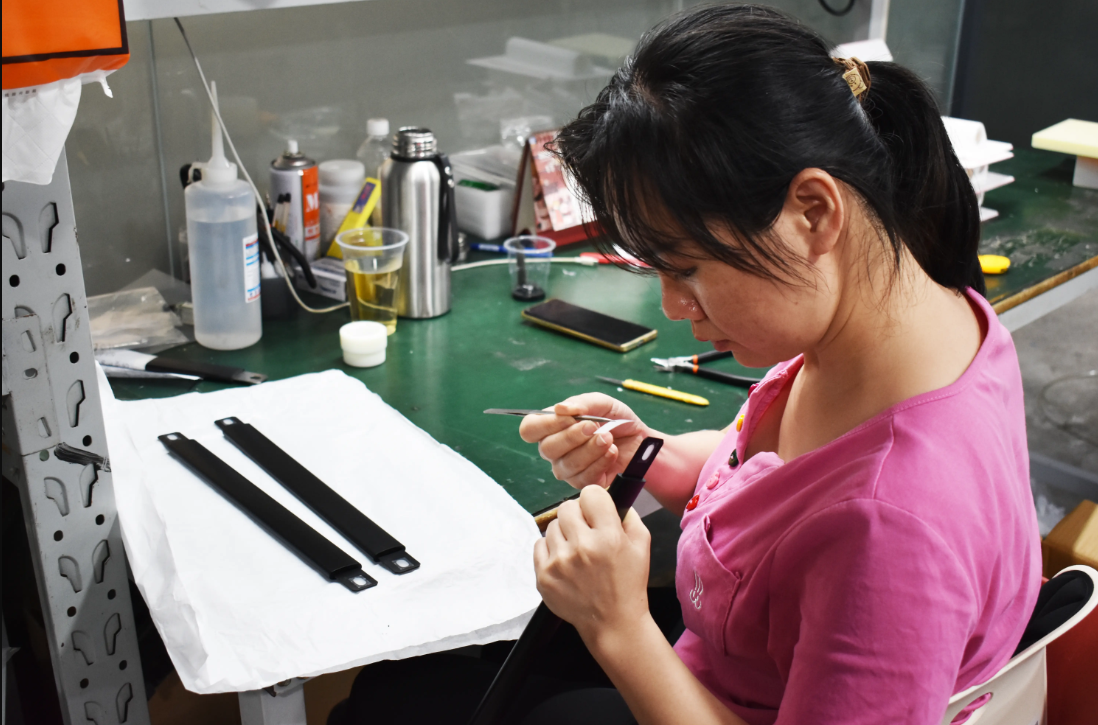

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: