- Product Detail

-

Plating of Plastics

Plating of plastics is a technique to form a metal film on plastic materials, mainly to improve their appearance, conductivity, and corrosion resistance. The main processes are as follows

Pretreatment

Degreasing: Oil stains and dust adhering to the plastic surface are removed using a surfactant or organic solvent. Afterwards, the surface is thoroughly rinsed with water.

Roughening: Roughen the plastic surface to improve adhesion to the plating film. Generally, this is done with a solution containing chromic acid or sulfuric acid. After roughening, the surface is then rinsed with water.

Catalyst treatment: A catalyst (mainly a solution containing tin or palladium) is deposited on the plastic surface to promote metal deposition in the next process.

Activation: After catalyst treatment, the surface is treated with an activating solution (e.g., a solution containing palladium chloride) to activate the catalyst.Plating Process

Nickel plating: Nickel plating is performed first. The plastic is immersed in a nickel plating solution to form a nickel film through electrolytic or electroless plating. This film serves as a base layer to improve adhesion and corrosion resistance.

Chrome plating (optional): Chrome plating is sometimes applied on top of nickel plating. Chrome plating can further enhance luster, wear resistance, and corrosion resistance.Post-treatment

Rinsing: After plating, residual plating solution on the surface is completely removed by rinsing.

Drying: After rinsing, dry the plating by an appropriate method. Natural drying and warm air drying are available.

Inspection: The appearance, adhesion, thickness, etc. are inspected to confirm quality.

Plating crafts of plastics are widely used in many fields such as automotive parts, home appliances, and decorative parts.

Cutting + Plating

Material :ABS Processing method:Cutting + Plating Processing time:5-7 days

Category:

Keywords:

Plating

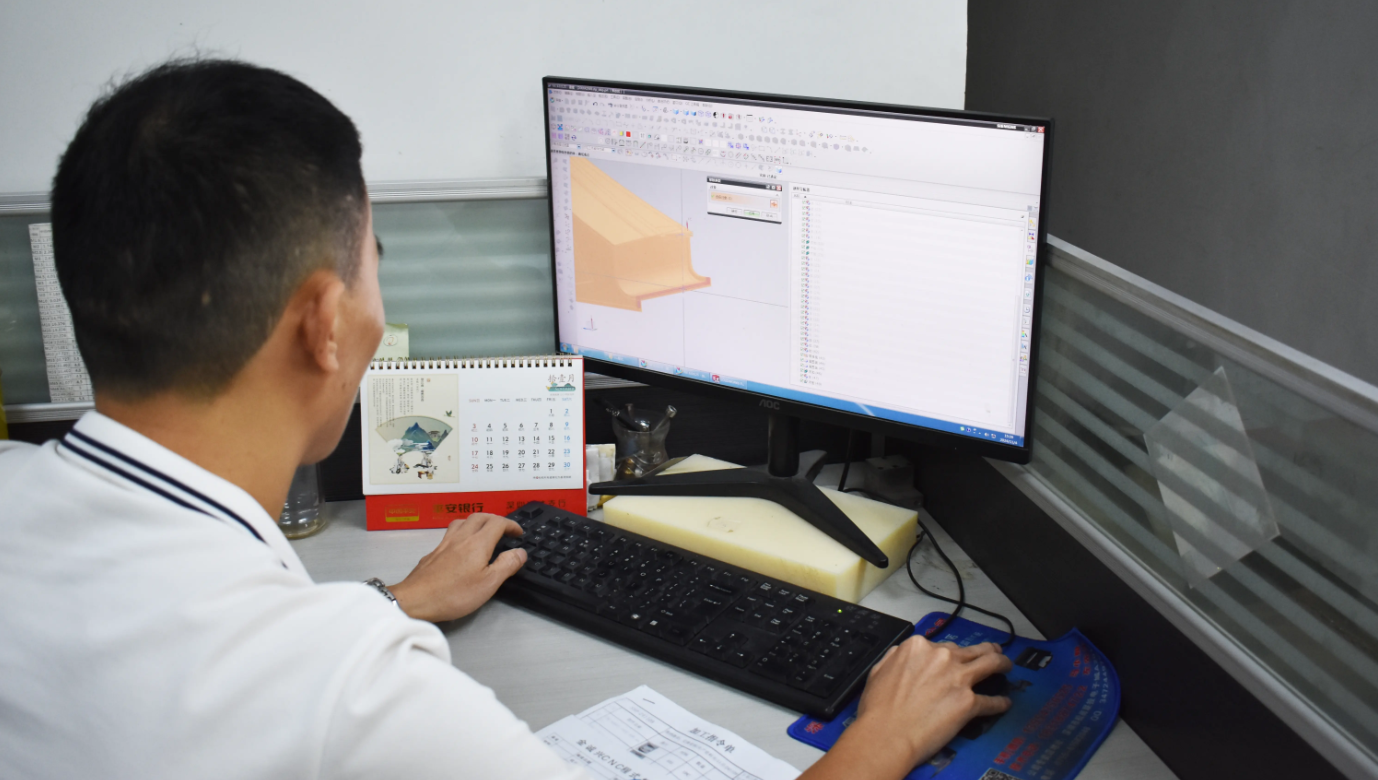

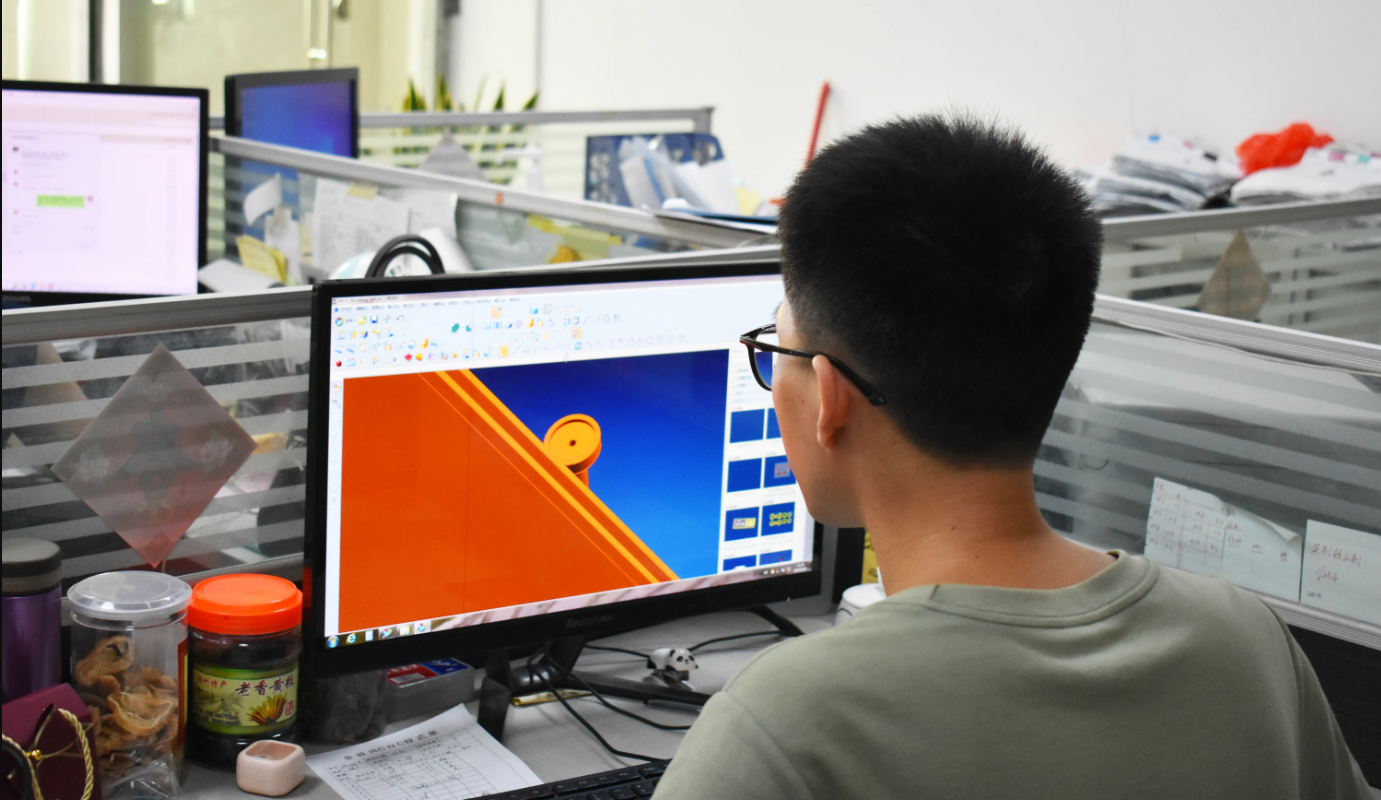

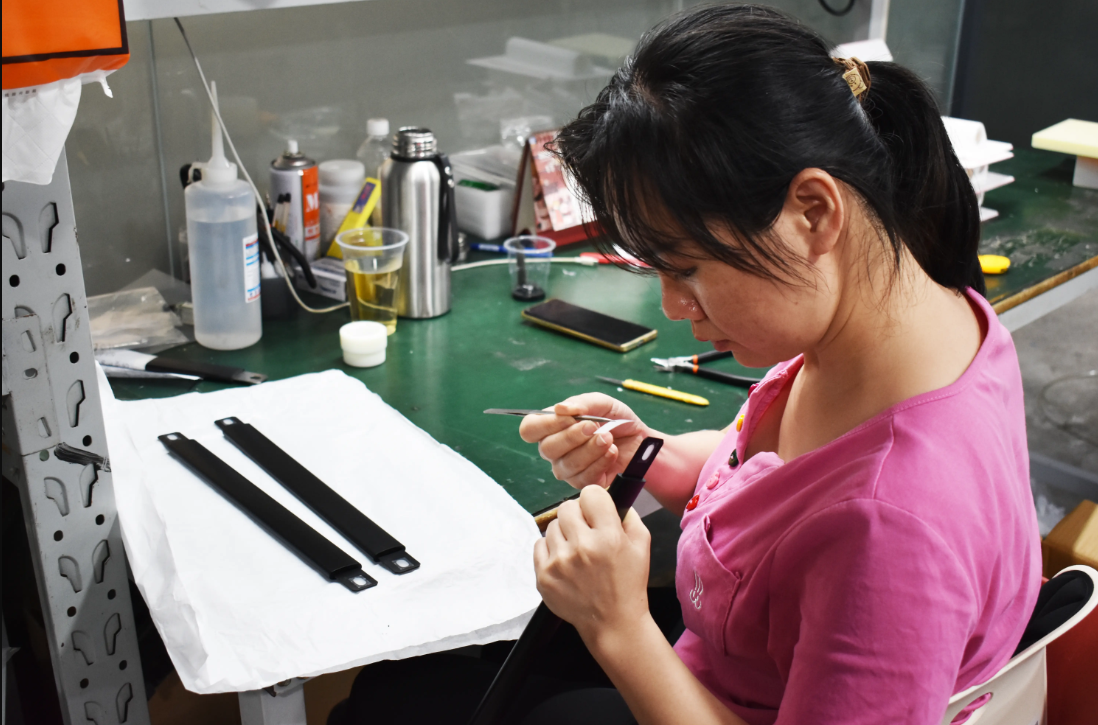

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: