- Product Detail

-

What is secondary machining?

Secondary machining is a machining process that is performed to further improve the accuracy, function, or appearance of a material after it has been machined to its basic shape in primary machining. Below are typical types of secondary machining and their characteristics.

Cutting

This is a machining method to obtain high-precision dimensions and surface roughness by cutting the surface of the part obtained in the primary machining process. Machine tools such as lathes, milling machines, and drilling machines are used. For example, it is used to make the outer diameter of a shaft accurate or to smooth the flat surface of a part.

GrindingThis process is used to further smooth and luster the surface after cutting. Methods include buffing, sandpaper polishing, and wheel polishing. The main purposes of this process are to improve appearance, reduce friction resistance, and improve corrosion resistance. It is often used for automobile bumpers and exterior parts of home appliances.

Secondary Processing of PlasticsThermoforming: Plastic sheets or molded products are heated to soften and then placed in a mold to be formed into the desired shape. Blow molding and vacuum molding are examples. Used in the manufacture of containers, automotive instrument panels, etc.

Printing and labeling: Plastic products are printed or labeled with text, graphics, designs, etc., on the surface to enhance product identification and design. This is widely used for containers of daily commodities, housings of electronic devices, etc.

Secondary Processing of MetalsPlating: A process to coat the surface of a metal product with another metal to improve corrosion resistance, decorativeness, electrical conductivity, etc. Nickel plating, chrome plating, and copper plating are examples. It is widely used for automotive parts, electrical equipment parts, etc.

Welding: A processing method to join two or more metal parts. Arc welding, laser welding, resistance welding, etc. are used. This process is indispensable for assembling machine parts and manufacturing structures.

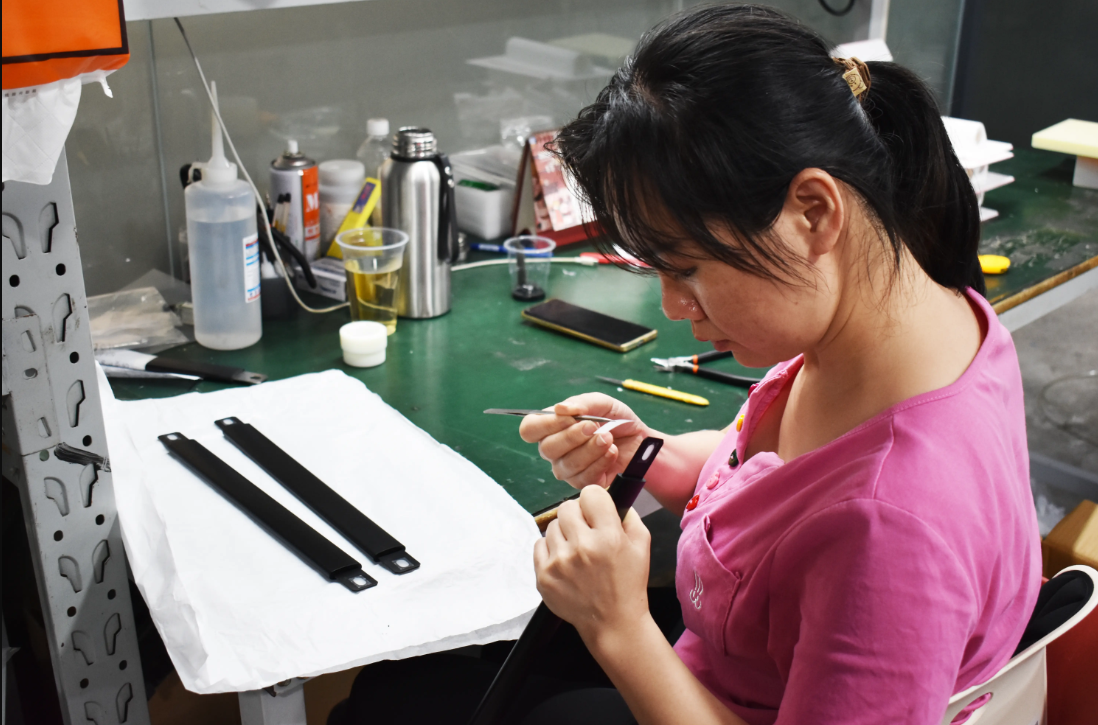

Lathe turning + secondary additive worker

Material SUS Processing method: Lathe turning + secondary additional work Processing time: 4-5 days

Category:

Keywords:

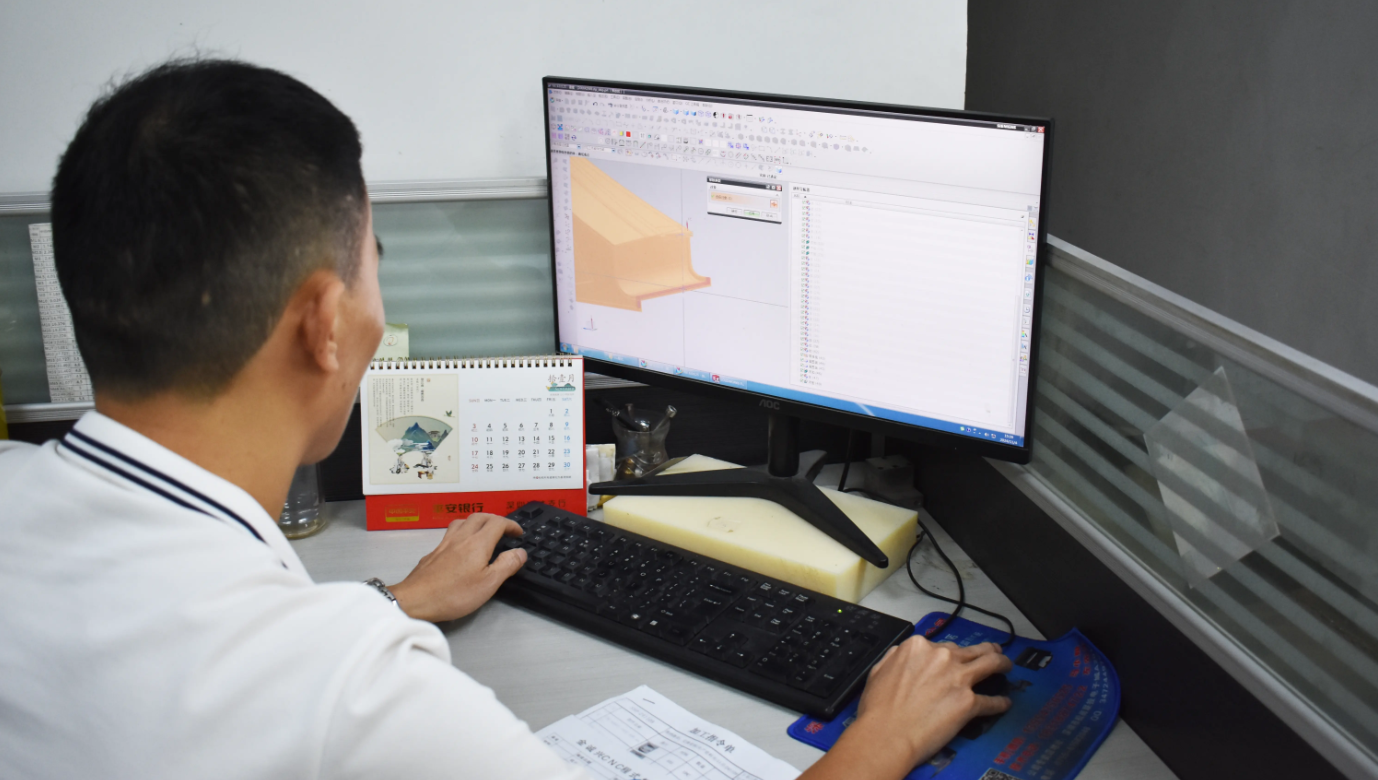

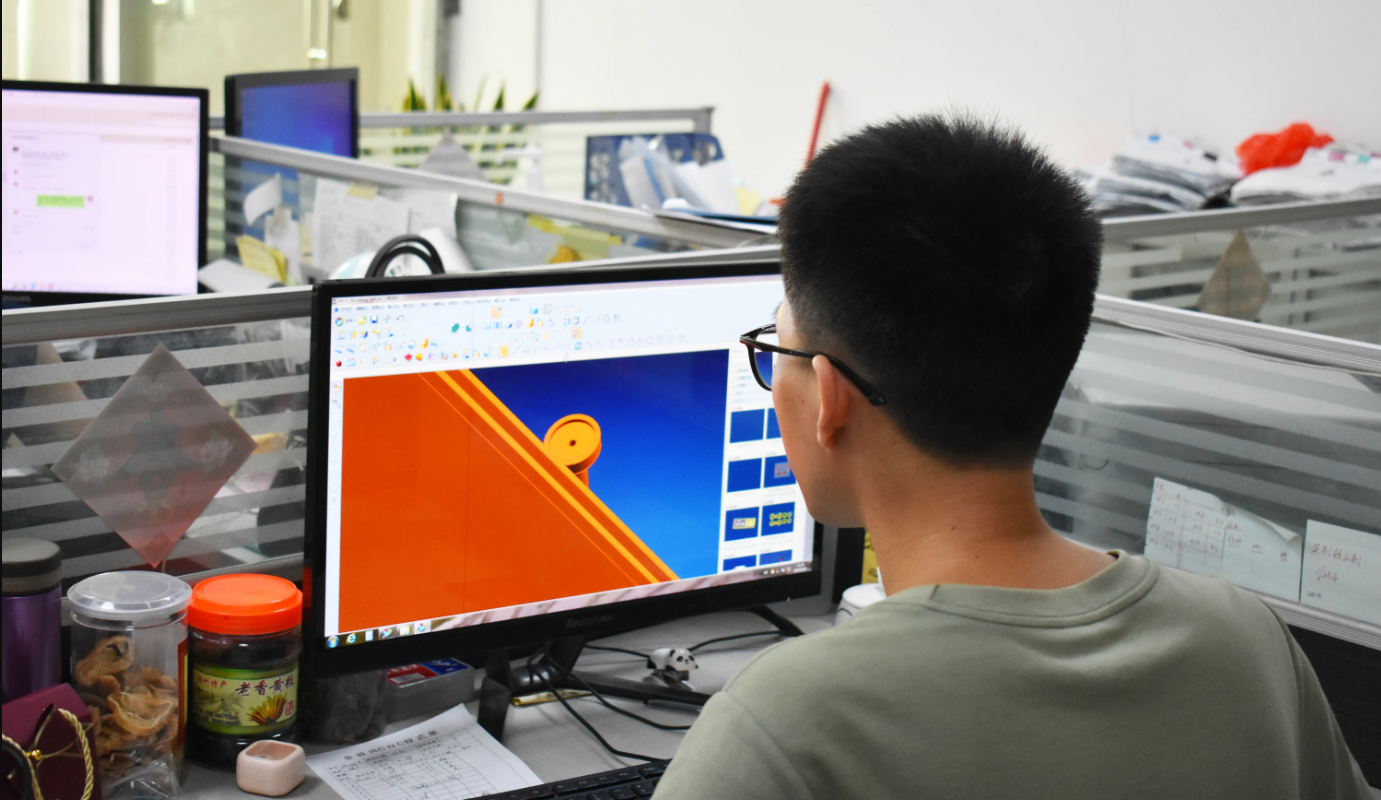

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: