- Product Detail

-

Vacuum Molding:.

Vacuum molding is a technique to produce molds of the same shape using silicone material, mainly based on a prototype.

of the same shape using silicone material, mainly based on a prototype. The main processes and features are

Prototyping: First, a prototype of the product is created by 3D printing or cutting.

This prototype accurately reproduces the shape and details of the final product.

Silicone injection: The prototype is placed in a mold and silicone rubber is injected around it.

Silicone rubber is fluid and can cover even the smallest irregularities and curved surfaces of the prototype.

Silicone rubber is fluid and can cover even the smallest irregularities and curved surfaces of the prototype.

Curing: After injection, the silicone rubber is left to cure for a certain period of time. The curing time depends on the type of silicone and additives.

The curing time varies depending on the type of silicone and additives, but generally ranges from a few hours to a full day or night.

The curing time varies depending on the type of silicone and additives.

Mold demolding: After curing is complete, remove the mold from the silicone mold.

Remove the mold from the silicone mold. At this time, the mold and the silicone mold are cleanly separated, and the silicone mold is left with the exact shape of the mold.

The silicone mold has the exact shape of the original mold.

Resin injection: Next, materials such as resin are injected into the silicone mold. The resin

The resin is cured in the mold, and a product with the same shape as the prototype is produced.

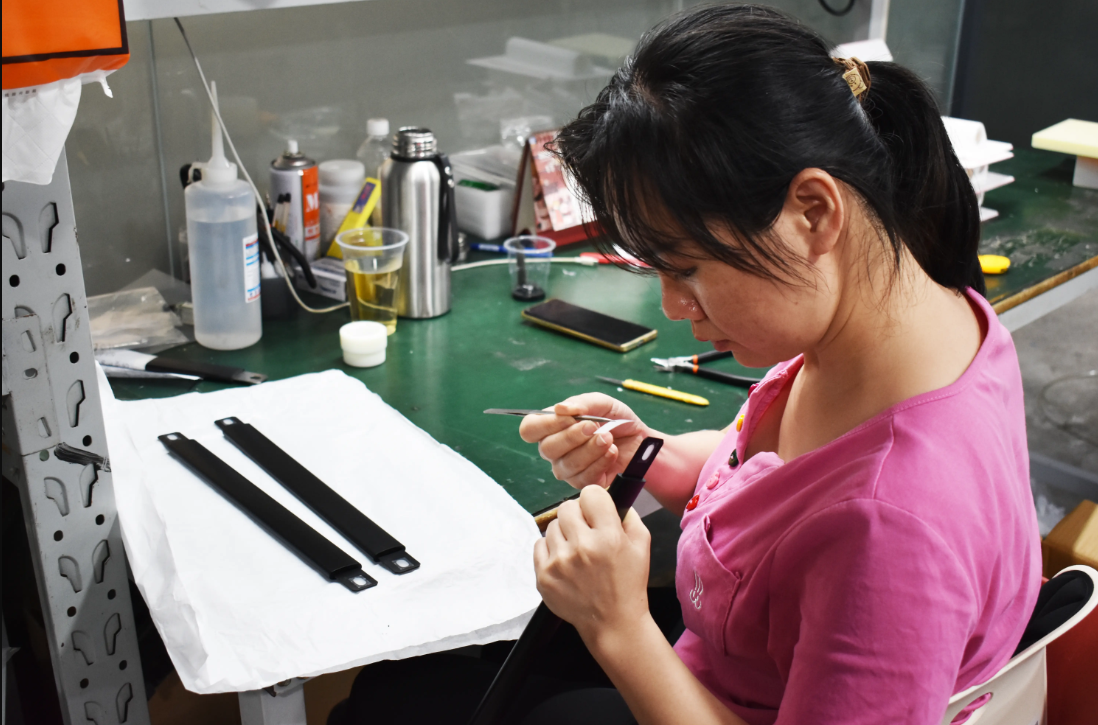

Product removal: Once the resin has cured, the silicone mold is opened and the product is removed.

After the resin has cured, the silicone mold is opened and the product is removed. If necessary, surface treatment or finishing of the product is performed.

The silicone copy mold process is relatively inexpensive and can produce a large number of samples in a short period of time.

The silicone copy mold process is relatively inexpensive and can produce a large number of samples in a short period of time. The silicone copy mold process is relatively inexpensive and can produce a large number of samples in a short period of time.

The silicone copy mold process is widely used in the development stage of new products and for small-lot production.

Vacuum casting - Urethane rubber

Material: Urethane gome Processing method: Vacuum casting Processing time: 6-7 days

Category:

Keywords:

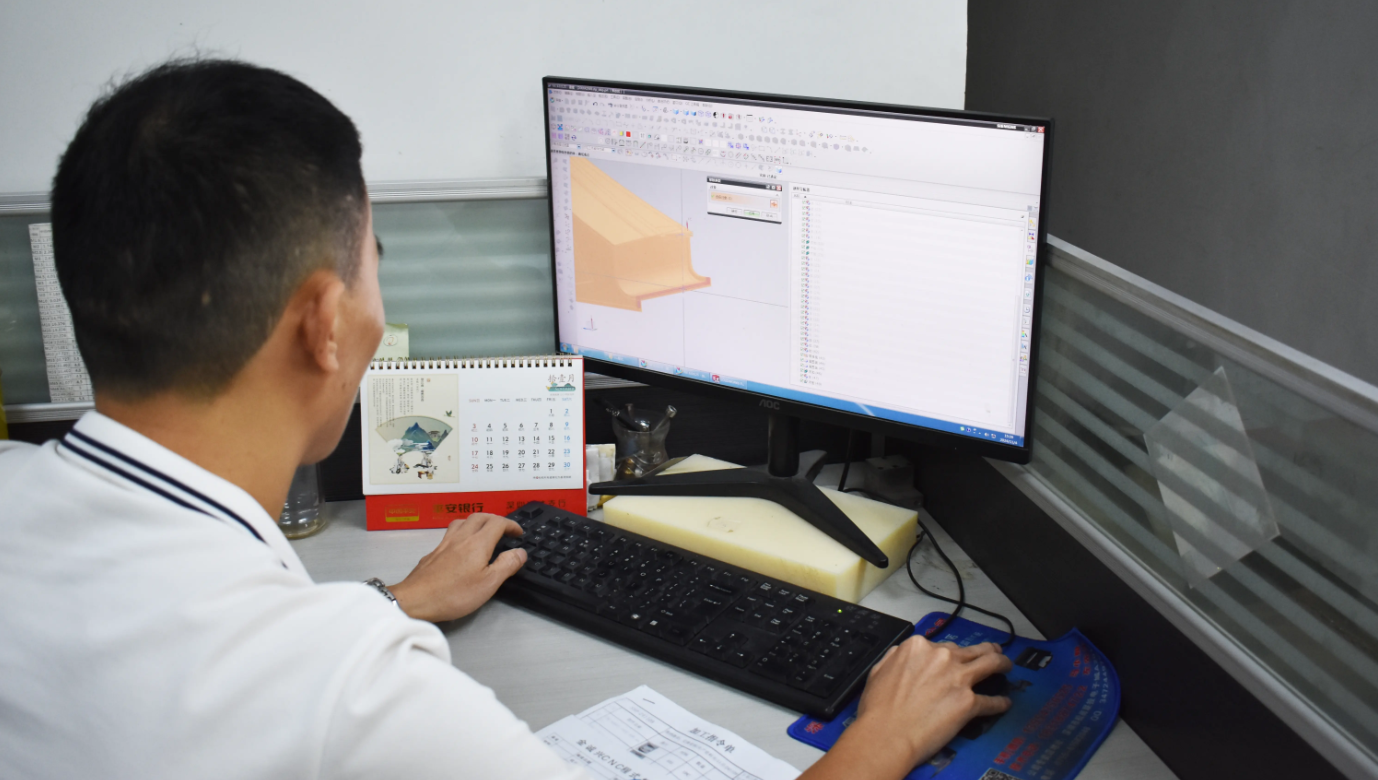

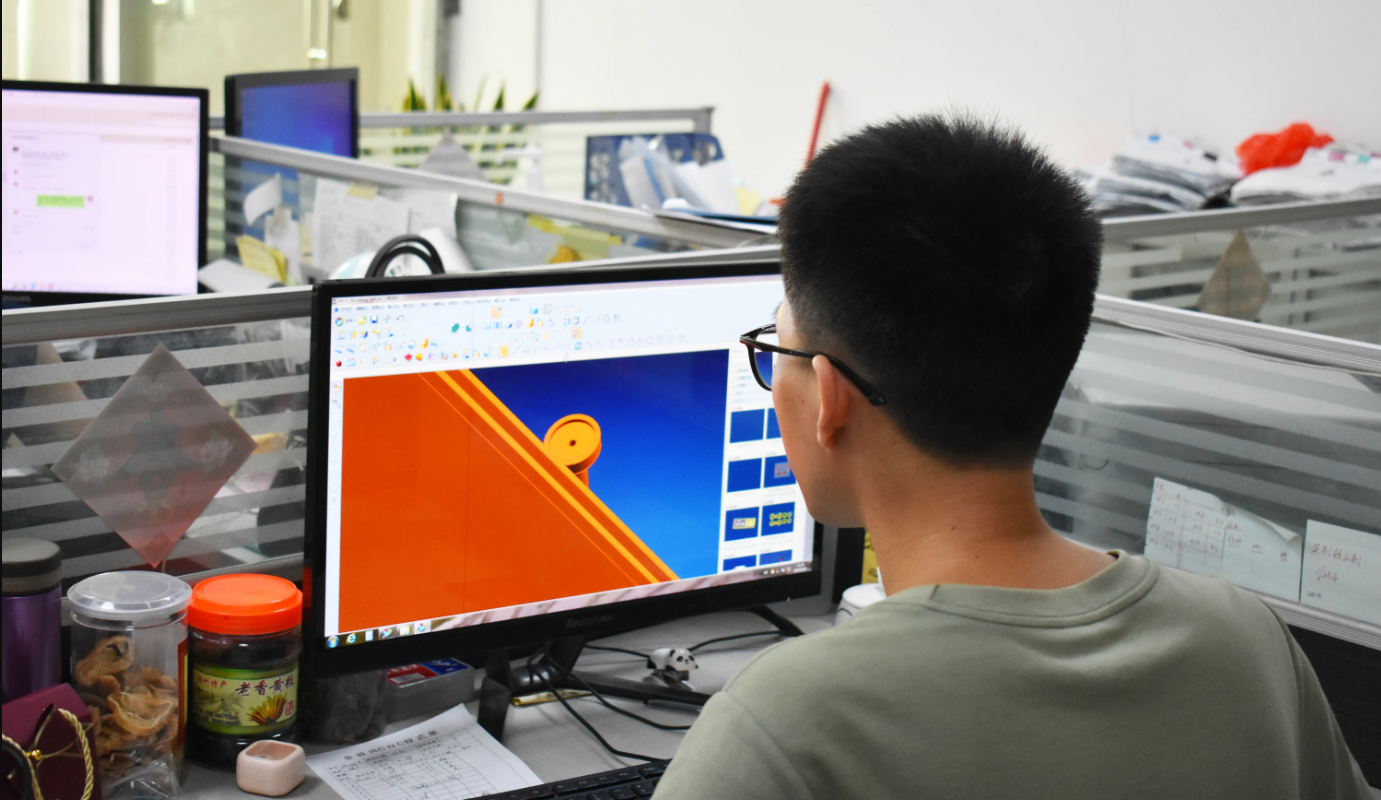

Factory Display

Q&A

Related Products

Inquiry Hotline:

Inquiry Hotline: