What are the processing steps for sheet metal fabrication?

Material Selection: Depending on product needs and design requirements, select appropriate metal sheets such as stainless steel, aluminum alloys, copper, etc.

Design and Drawing: Convert product designs into concrete 2D or 3D graphics using CAD or other design software.

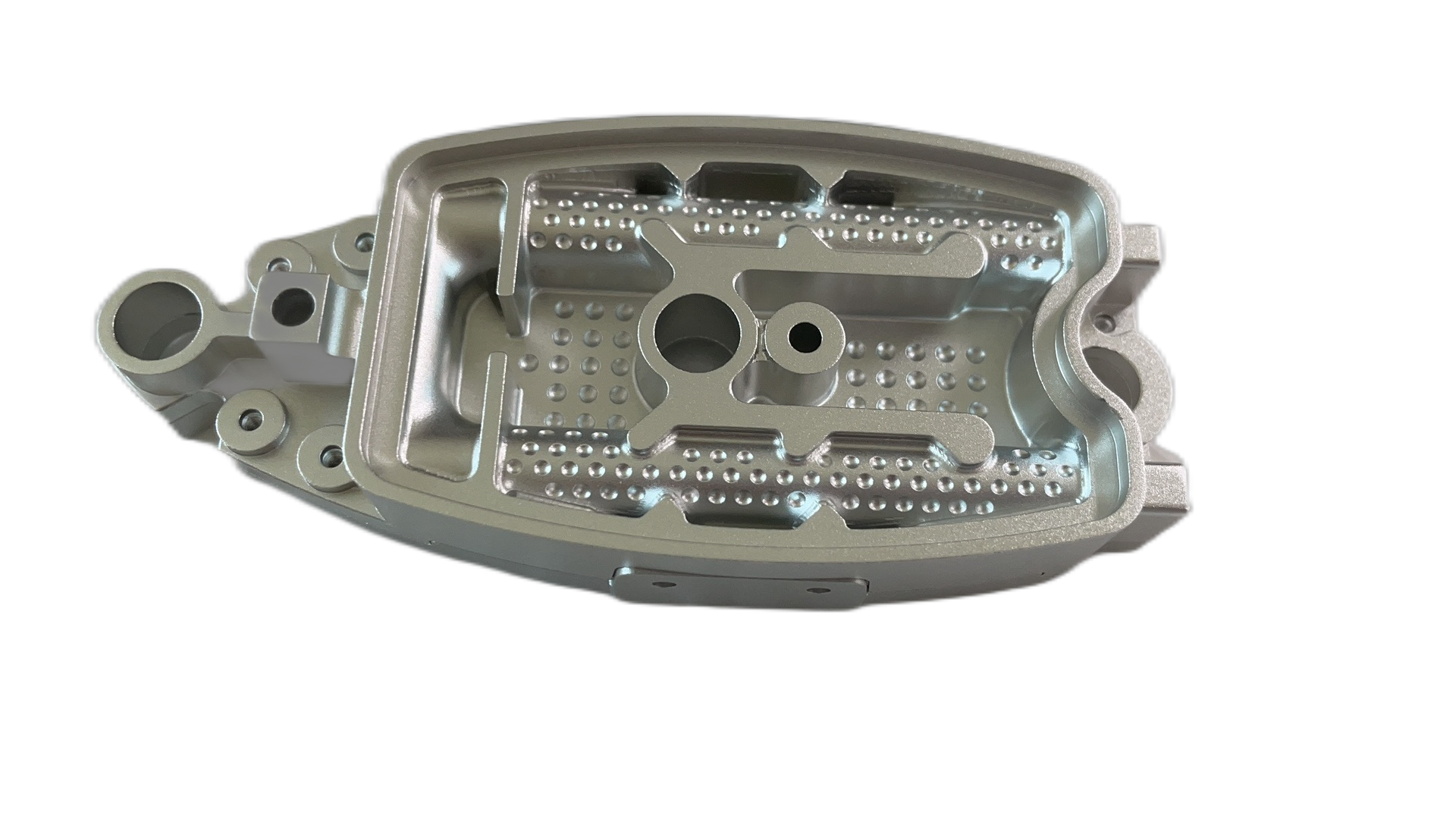

Cutting and ejection: Cut metal sheets to the required shape and size using equipment such as laser cutting machines, mechanical shears, and CNC punching machines.

Bending and Shaping: Cut metal sheets are bent to pre-set angles and shapes using bending machines.

Stamping: Metal material is stamped into the required shape using stamping machines.

Welding: Arc welding, gas welding, or other methods are used to connect multiple parts as a whole.

Surface treatment: Thermal spraying, plating, oxidation treatment, etc. are performed as needed to enhance the aesthetics and corrosion resistance of the product.

Quality inspection: Perform rigorous quality inspections of finished products to ensure that products meet design requirements and quality standards.

Packaging and transportation: Quality-assured products are packaged to prevent damage during transportation and delivered to the customer's designated location.

Sheet metal fabrication has a wide range of applications in machinery manufacturing, electronics and electrical equipment, the automotive industry, and architectural decoration. Sheet metal fabrication is used in these sectors to make a variety of parts, including shells for machinery and equipment, chassis for electronic products, and bodies and chassis for automobiles.

Related news

2025-12-10

Inquiry Hotline:

Inquiry Hotline: